News

Understanding and Managing Combustible Dust Hazards in Industrial Facilities

Combustible dust hazards represent a serious—but often underestimated—threat to industrial safety. Whether in manufacturing, food processing, or metalworking, any facility that handles fine particulate materials is at risk for fire, deflagration, or a catastrophic industrial dust explosion.

At Crow Engineering, we specialize in helping businesses proactively manage combustible dust safety, ensuring your operations remain productive and compliant—without compromising safety.

Read MoreCrow Engineering Partners with RIOS to Revolutionize the Wood Products Industry

Crow Engineering is excited to announce our partnership with RIOS to drive innovation, enhance capabilities, and improve efficiency in the wood products industry.

Read MoreRealize the Many Benefits of Optimizing Processes

Optimizing Processes is a necessity to remain competitive in any manufacturing market. Organizations across all sectors recognize the immense benefits of streamlining their operations to increase efficiency, reduce costs, and enhance overall performance. The Many Benefits of Process Optimization Optimizing processes entails examining and improving existing business functions to make them more efficient and effective.…

Read MoreAnother Year to Remember or Another Year to Forget? 2021 in Review

Looking back on 2021, one thing is clear: the lumber and wood products industries, like much of America and much of the world, is still contending with the impact of the COVID-19 pandemic. 2021 was a year in which lumber prices skyrocketed and then dropped.

Read MoreIs Your Fabricator All That? Three Keys for Measuring Value.

At Crow, one of our goals is to be the first-place mills turn to improve their operations. Traditionally, we’ve pursued this goal by providing capital and maintenance project support services.

Read MoreImproving productivity with PLC programming

If you need to upgrade or improve your PLC systems, start by collecting detailed field notes of equipment, wiring, functions, etc.

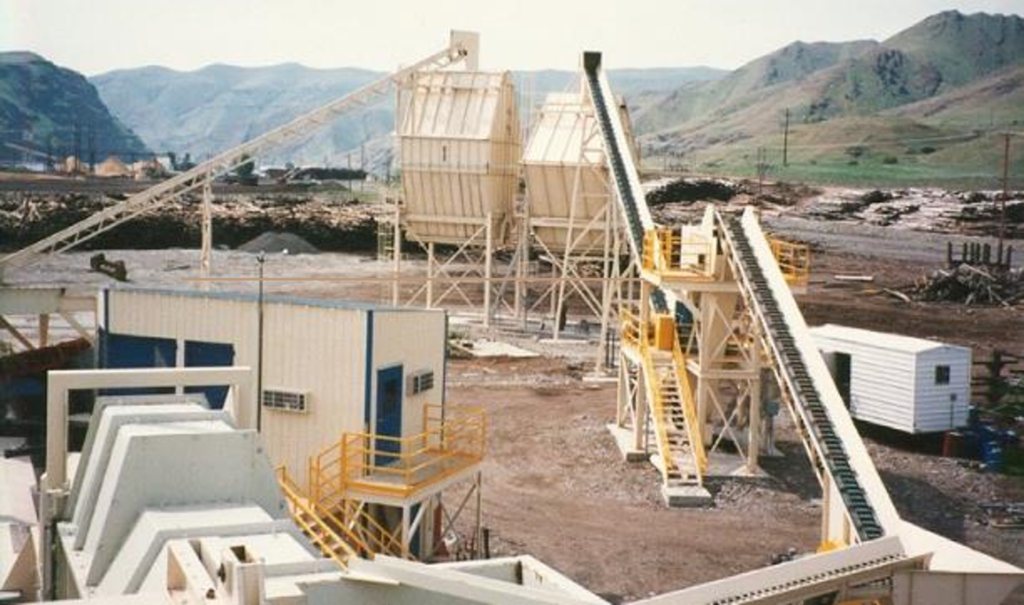

Read MoreMany investments and upgrade projects continue to emerge in the US South

The industry knows that the US needs to add about 1.5 million new homes per year to keep pace with population growth and replace existing homes. Forecasters indicate that lumber capacity in North America will fall short of new demand by close to 7 BBF which is equivalent to more than 20 large-capacity sawmills.

Read MoreThe time is now for a structural assessment

To ensure safety and minimize the risk of operational shutdowns at a time of high demand, many mills commission a structural assessment of critical facilities. Such assessments typically involve an analysis and evaluation of foundations, framings, and associated construction systems and details.

Read MoreCan’t Fill Your Manufacturing Jobs? Read This Before It’s too Late: 3 Keys to Attracting and Keeping Manufacturing Employees

In March 2021, activity in the sector surged to a 37-year high. An estimated half million jobs in manufacturing remain unfilled. Across the spectrum – from low-skilled entry-level positions to specialized roles such as welders and machinists — factory operators find it increasingly difficult to find the workers they need.

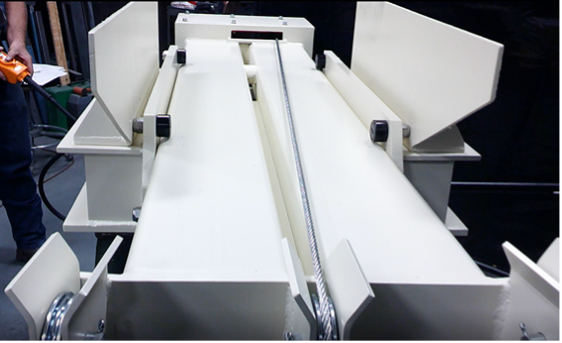

Read MoreLooking to Upgrade a Conveyor? Ask These Questions First

When it comes to upgrading conveyors, it’s important to move deliberately. For starters, you’ll need to assess the space, infrastructure, and equipment in place.

Read More