Equipment Configuration Specialists

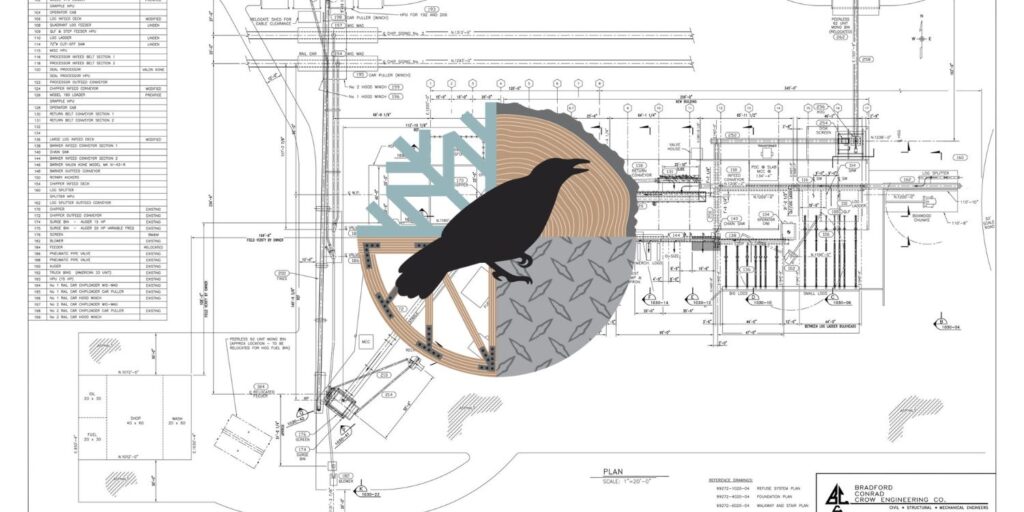

The team at Crow Engineering offers experience in a wide range of machinery and equipment to provide Overall Equipment Effectiveness (OEE) improvement. We specialize in machine and equipment engineering and design, layouts, maintenance, engineering, and reliability support. We coordinate with OEM vendors for integration into the overall plant and product line layout.

Optimal Equipment Placement

Strategically positioning machinery to ensure smooth workflow and operational efficiency.

Workflow Optimization

Designing equipment layouts that streamline production processes and minimize material handling.

Safety & Compliance Planning

Configuring equipment to meet safety standards and regulatory requirements, ensuring a secure working environment.

Energy Efficiency Enhancement

Arranging equipment to reduce energy consumption and promote sustainable operations.

Technology Integration

Incorporating advanced technologies such as automation, robotics, and IoT devices into equipment layouts.

Maintenance Accessibility Design

Ensuring equipment layouts allow easy access for maintenance and repairs, minimizing downtime.

Equipment Configuration Specialists

The team at Crow Engineering offers experience in a wide range of machinery and equipment to provide Overall Equipment Effectiveness (OEE) improvement. We specialize in machine and equipment engineering and design, layouts, maintenance, engineering, and reliability support. We coordinate with OEM vendors for integration into the overall plant and product line layout.

The specific details of equipment configuration will vary greatly depending on the type of industry, the nature of the operations, and the specific equipment and machinery involved. Engineering and design services for equipment configuration aim to optimize these aspects to enhance productivity, safety, and efficiency in commercial and industrial settings. Contact us to learn more about Crow Engineering’s complete solutions for optimal equipment configuration.

Industries We Serve

At Crow Engineering, we are committed to delivering innovative, efficient, and cost-effective engineering and design solutions across a wide range of industries. Contact us today to discuss your project and discover how we can help you achieve your goals. Your success is our priority.

Full-Service Engineering, Project, and Construction Management Support

- Crow Engineering provides comprehensive support for wood processing facilities, from concept to completion.

- Our project and construction management expertise ensures successful outcomes.

Custom Machinery and Material Handling Design

- We specialize in designing custom machinery and material handling systems for the forestry and lumber industry.

- Tailored solutions to optimize wood processing operations.

Consulting and Estimation Services

- Crow Engineering offers consulting and estimation services throughout the capital process.

- We help you make informed decisions and manage costs effectively.

Owners Representation

- We act as your trusted representative throughout the project, ensuring your interests are protected.

Full-Service Engineering, Project, and Construction Management Support

- Crow Engineering provides comprehensive support for industrial and manufacturing facilities.

- Our project and construction management expertise ensures successful outcomes.

Custom Machinery and Material Handling Design

- We specialize in designing custom machinery and material handling systems for industrial and manufacturing processes.

- Tailored solutions to optimize your operations.

Consulting and Estimation Services

- We specialize in designing custom machinery and material handling systems for industrial and manufacturing processes.

- Tailored solutions to optimize your operations.

At Crow Engineering, we are committed to delivering innovative, efficient, and cost-effective engineering and design solutions across a wide range of industries. Contact us today to discuss your project and discover how we can help you achieve your goals. Your success is our priority.

Full Architectural and Structural Design Services

- Crow Engineering provides complete architectural and structural design solutions for cold storage facilities.

- Our designs prioritize energy efficiency and storage capacity.

Site Planning and Civil Engineering

- We excel in site planning and civil engineering, ensuring that your cold storage facility is optimized for your company’s needs.

Electrical and Controls

- Our electrical and controls expertise ensures that your cold storage facility operates reliably and efficiently.

- Customized solutions for automation and monitoring.

Full Architectural and Structural Design Services

- Crow Engineering delivers architectural and structural design services for distribution facilities.

- Our designs prioritize efficiency, accessibility, and storage capacity.

Site Planning and Civil Engineering

- We excel in site planning and civil engineering, optimizing the layout of distribution facilities for smooth operations.

Electrical and Controls

- Our electrical and controls solutions enhance the functionality and reliability of distribution facilities.

- We customize designs to meet your specific needs.

Material Handling and Storage Design

- Crow Engineering specializes in designing material handling and storage systems to maximize efficiency and productivity.

- We provide complete design services for conveyance, transfer, and bulk material handling needs.

Support Steel, Walkway, and Platform Design

- Crow Engineering excels in designing structural systems for chemical plants.

- Our solutions prioritize safety, functionality, and compliance with industry standards.

- Innovative engineering to support your chemical processing operations.

Civil Engineering Support

- Our civil engineering expertise includes site preparation and infrastructure design.

- We ensure the seamless integration of chemical facilities into their surroundings.

Process Equipment Integration

-

- We specialize in integrating process equipment into chemical plants, optimizing operations and efficiency.

- Precision engineering to streamline your chemical processing.

Feedstock Handling Systems

- We design and optimize feedstock handling systems for energy production.

- Our solutions ensure the efficient supply of raw materials to energy facilities.

Boiler Integration

- Crow Engineering excels in integrating boilers into complicated existing arrangements.

- We excel at developing plans for the replacement of these systems in extremely challenging locations.

Electrical and Controls

- Our electrical and control solutions enhance the reliability and performance of energy facilities.

- We customize designs to meet your boiler and steam control needs.

Full-Time Construction Management, Scheduling, and Vendor Management

- Crow Engineering offers comprehensive construction management services.

- We handle scheduling and vendor management to ensure projects stay on track.

- Full vendor and contractor management on behalf of your organization.

- Full time onsite support services throughout the life of the project.

Construction Engineering

- Our construction engineering expertise can help assist with the most challenging equipment installations.

- Full customized design for unique lifting, shoring, equipment setting, and repair needs during installation.

Inspection Support

- We provide inspection support to ensure that construction projects meet all regulatory and quality standards.

the crow connection

Recent News

The Crow Connection delivers high-level insights on engineering, automation, and process optimization, helping you drive efficiency and innovation. Covering topics like AI-powered automation, manufacturing strategies, and industrial process improvements, it’s a must-read for leaders seeking a competitive edge.