The Crow Connection

The Primary Goals of a Facility Performance Evaluation

How Building Performance Evaluations Increase Efficiency

The Essentials of Building Condition Assessments: Ensuring Safety and Efficiency

Crow Engineering Partners with RIOS to Revolutionize the Wood Products Industry

Crow Engineering is excited to announce our partnership with RIOS to drive innovation, enhance capabilities, and improve efficiency in the wood products industry.

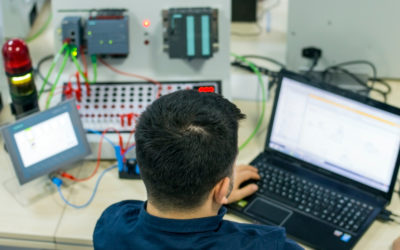

Allen-Bradley PLCs: Revolutionizing Integrated Control Systems

Why Accurate Capital Cost Estimation Is Important- Infographic

How Control Systems Improve Wastewater Efficiency

Benefits of a Constructability Review

Developing an Industrial Plant Layout- Infographic

Realize the Many Benefits of Optimizing Processes

Equipment Efficiency Optimization: Maximize Manufacturing Processes Strategically

Automation Machines: Revolution In Manufacturing

Project Rationalization for Critical Business Ventures

Types of 3D Scanning Technology: Pros & Cons

Illuminating Success: The Critical Role of Industrial Lighting

The Process of Achieving Optimal Plant Layout -Infographic

Transforming Manufacturing Efficiency: Process Optimization Strategies

Greenfield vs. Brownfield Projects: Navigating Complexities with Engineering Solutions

Maximizing Operational Efficiency: The Power of Process Optimization

Manufacturing Process Optimization: Elevating Efficiency and Profitability

What is an Optimal Plant Layout Design?

Plant Layout Optimization Techniques: Enhancing Manufacturing Productivity

Another Year to Remember or Another Year to Forget? 2021 in Review

Looking back on 2021, one thing is clear: the lumber and wood products industries, like much of America and much of the world, is still contending with the impact of the COVID-19 pandemic. 2021 was a year in which lumber prices skyrocketed and then dropped.

Is Your Fabricator All That? Three Keys for Measuring Value.

At Crow, one of our goals is to be the first-place mills turn to improve their operations. Traditionally, we’ve pursued this goal by providing capital and maintenance project support services.

Improving productivity with PLC programming

If you need to upgrade or improve your PLC systems, start by collecting detailed field notes of equipment, wiring, functions, etc.

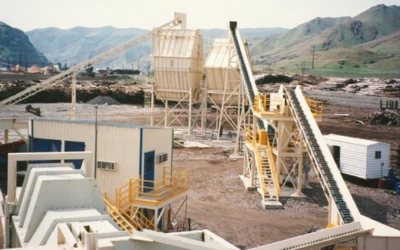

Many investments and upgrade projects continue to emerge in the US South

The industry knows that the US needs to add about 1.5 million new homes per year to keep pace with population growth and replace existing homes. Forecasters indicate that lumber capacity in North America will fall short of new demand by close to 7 BBF which is equivalent to more than 20 large-capacity sawmills.

The time is now for a structural assessment

To ensure safety and minimize the risk of operational shutdowns at a time of high demand, many mills commission a structural assessment of critical facilities. Such assessments typically involve an analysis and evaluation of foundations, framings, and associated construction systems and details.

Can’t Fill Your Manufacturing Jobs? Read This Before It’s too Late: 3 Keys to Attracting and Keeping Manufacturing Employees

In March 2021, activity in the sector surged to a 37-year high. An estimated half million jobs in manufacturing remain unfilled. Across the spectrum – from low-skilled entry-level positions to specialized roles such as welders and machinists — factory operators find it increasingly difficult to find the workers they need.

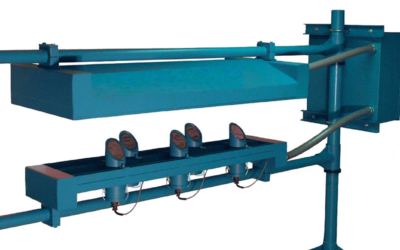

Why Is My Blow Detector Inconsistent?

There are two primary problems with ceramic crystal transducers used in blow detectors. The first is that they’re finely tuned devices (with a high Q factor) where the transmitter and receiver need to operate within in an exceptionally narrow frequency band.

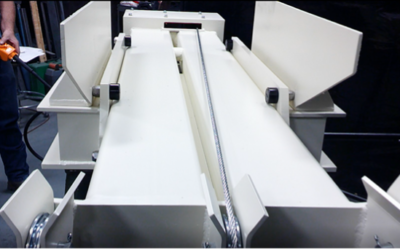

Looking to Upgrade a Conveyor? Ask These Questions First

When it comes to upgrading conveyors, it’s important to move deliberately. For starters, you’ll need to assess the space, infrastructure, and equipment in place.

Why Plant Modernization? Four Reasons to Go with a Brownfield Expert

Structures and equipment don’t last forever. At some point, they begin to exhibit signs of wear and tear. Eventually, you need to take action. Which is what ‘brownfield” plant modernization is all about. There’s a lot of value in the equipment you already have – and with plant modernization, you can keep on generating value for years to come.

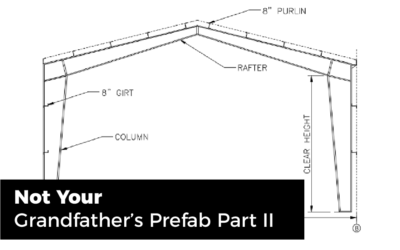

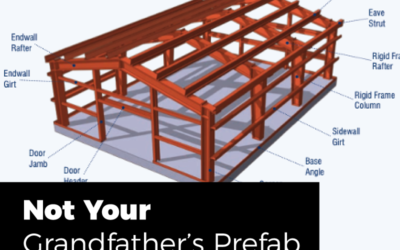

Specification and Design of Pre-engineered Metal Buildings (Part II)

In the first part of this article, we looked at the basics and dimensions of metal buildings for industrial settings. In this second part of the article, we explain the design criteria and specifications of pre-engineered metal buildings.

Specification and Design of Pre-engineered Metal Buildings (Part I)

Pre-engineered metal buildings are common features in industrial settings. In fact, they have become common features in many types of construction from utilitarian sheds to keep out the elements to multi-story architectural buildings for just about any use. This is the first part of an article looking at specifying metal buildings for industrial settings.

Helping Sawmills Manage Demand

Crow has helped customers save millions of dollars in capital expenses by re-purposing current facilities and equipment on site. If you’re in the lumber business, it’s hardly news that demand has been outstripping supply – largely due to a pandemic housing boom that few saw coming. With new home building reaching a 15-year high, demand for new building materials such as 2×4 lumber is through the roof.

Why Risk Based Safety?

Keep the risk low, keep employees safe, and keep operations up and running – which keeps the revenue flowing.

Choosing the Right Partner

Choosing the right partners to support your project often determines the success of that project. What’s needed are vendors with subject matter expertise and a proven track record of success.

Earth, Wind, Fire, Water

Designing buildings to stand up to the elements requires detailed site analysis to determine weather patterns, climate, soil types, wind speed and directions, heat, path of the sun, and more. Solutions involving insulation, vapor barriers, and air barriers will vary radically depending on whether the site is in the cold and snowy north, the hot and humid south, or the arid desert.

AIC Systems Still Up and Running After 30 Years

In 1973, Automation Industries Corporation (AIC, now Miloptic) developed blow detectors that used air-coupled ultrasonic nondestructive testing technology. Now, several of the systems – installed more than 30 years ago at panel and flooring facilities – are still up and running.

Freres Lumber Builds a New Breezeway

Recently, Freres worked with Crow Engineering to design an open-sided structure using its MPP product. The aim of the project was to infill a space between two manufacturing buildings at the Freres Plant 3 mill in Mill City, OR.

Miloptic to Offer Ultrasonic Technology Through Acquisition of Automation Industries Corporation (AIC)

Miloptic, LLC is pleased to announce the acquisition of Automation Industries Corporation (AIC). This acquisition will allow Miloptic to offer a variety of nondestructive testing technology systems that ensure and improve the quality of building products through its parent company Crow Engineering, Inc. Clyde Steffens, former President of AIC, is serving as President of Ultrasonic Development for Miloptic.

The Crow Engineering Chess Tournament

Two players. One chess board. One move yields a countermove – attack and defend, strike and counterstrike. Warring adversaries fight it out by the rules of an ancient game. There’s a quiet but palpable tension in the room. Then a single word breaks the silence: “checkmate.”

Learn how Crow Engineering brought chess into the office.

Sawmill assessment brings big ROI

At Crow Engineering, relationships with customers last for years. One company – a long-term customer – recently engaged us to review ways to increase the productivity of its lumber manufacturing process. To assess and identify improvement opportunities, we conducted an efficiency study of the company’s log infeed and breakdown systems.

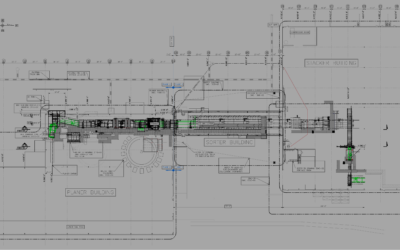

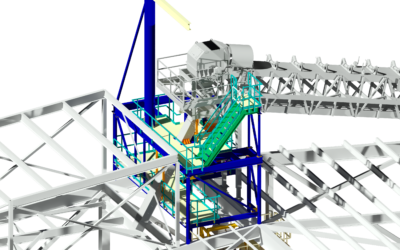

Modernizing a Mill with 3D

Recently, Crow Engineering completed an engineering design to replace a raw material infeed conveyor at a building products mill. The mill was connected to a mining operation with a single conveyor to deliver feedstock. The conveyor was built in 1962 and worn out. Any interruption or problems with this conveyor caused both mining and mill production to stop. The owner hired Crow to evaluate the situation and investigate possible solutions to replace, upgrade, or rebuild the raw material feed line.

Equipment Relocation, and installation.

Recently, Crow was hired by a client in the Northwest that wanted to replace an outdated planer mill. The client had identified a planer line located in the Southeast and hired Crow as the principal consulting engineer and the contractor responsible for disassembling, relocating, adapting, and installing this system in their facility. To accomplish the task, Crow divided the project in several phases.

New Crow Engineering Southeast Office

This office has allowed us to significantly expand our Southeast presence and deepen our engineering and project management expertise. This commitment to the Southeast region has already greatly increased our ability to service both new and existing clients within the forestry and building products industries.