Uncategorized

Improving productivity with PLC programming

If you need to upgrade or improve your PLC systems, start by collecting detailed field notes of equipment, wiring, functions, etc.

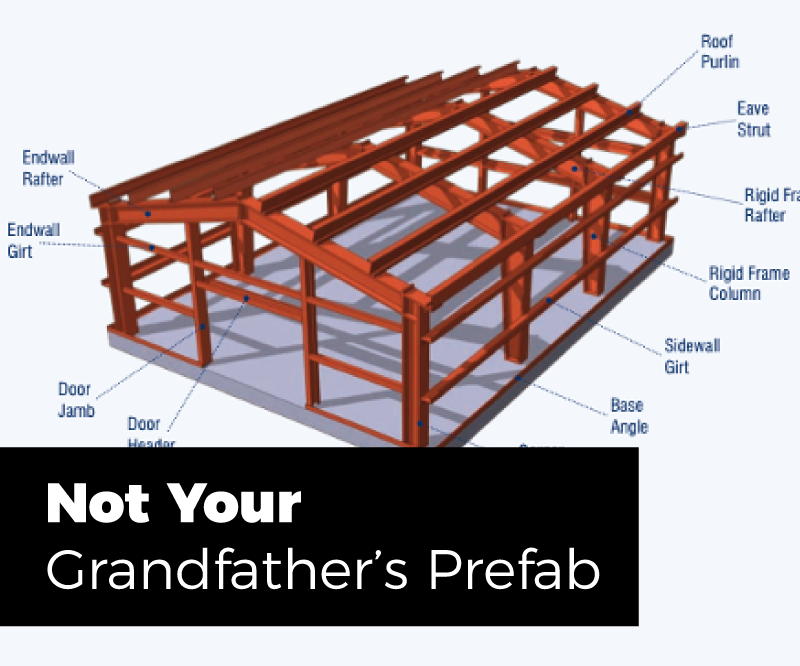

Read MoreSpecification and Design of Pre-engineered Metal Buildings (Part I)

Pre-engineered metal buildings are common features in industrial settings. In fact, they have become common features in many types of construction from utilitarian sheds to keep out the elements to multi-story architectural buildings for just about any use. This is the first part of an article looking at specifying metal buildings for industrial settings.

Read More