Miloptic to Offer Ultrasonic Technology Through Acquisition of Automation Industries Corporation (AIC)

Miloptic is pleased to announce the acquisition of Automation Industries Corporation (AIC). This acquisition will allow Miloptic to offer a variety of nondestructive testing technology systems that ensure and improve the quality of building products through its parent company Crow Engineering, Inc. Clyde Steffens, former President of AIC, is serving as President of Ultrasonic Development for Miloptic.

AIC: A pioneering history

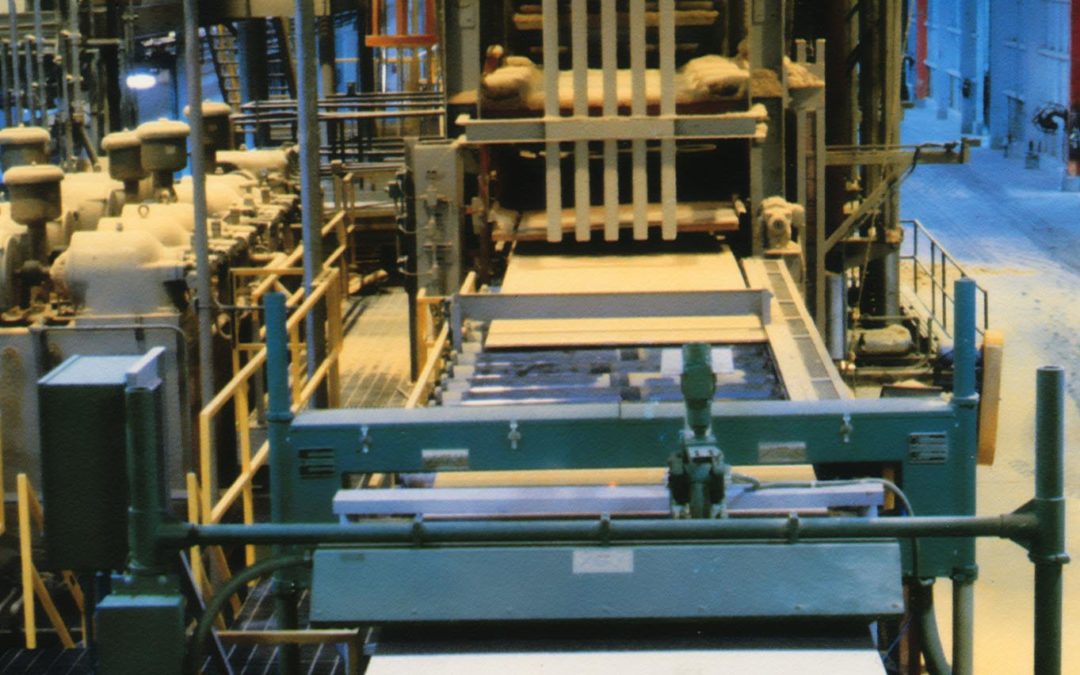

In the early 70’s, Clyde Steffens developed a technology that allowed plywood producers to eliminate blisters, blows, and other internal defects that lead to the delamination of panels. Along with American Plywood Association personnel, AIC visited plywood mills all over to demonstrate the first Trienco 506 ultrasonic NDT (non-destructive testing) system. With value demonstrated, installations followed.

Years later, Trus Joist approached Clyde based on his success in the plywood industry. They challenged Clyde to do the same for the LVL industry, a thicker and more structurally critical product. Taking the challenge, Clyde developed a higher strength ultrasonic system for the industry that was a success.

Over the years, Clyde has developed multiple systems using ultrasonic and laser technology to solve similar problems across other industries. These include lumber, engineered flooring, gypsum, and corrugated and web roofing systems.

The present and future

Miloptic will continue to offer the same exceptional high-quality products that have helped AIC build a reputation as the best NDT testing manufacturer in the industry. We will continue to produce and support the existing product lines. We are committed to enhancing our current products while developing new and advanced NDT solutions in the years to come.

About Automation Industries Corporation

AIC has developed and refined ultrasonic technology applications for more than 40 years. The company’s current generation of machines can detect smaller defects and reliably penetrate thicker materials than prior generations. OSB and plywood defect detection systems have represented a significant portion of sales for AIC. The 5700 series systems are proven to reliably penetrate LVL and PSL300 that are 3.5” thick (the typical maximum thickness of LVL). CLT and other engineered wood systems are next on our list for development. While ultrasonic systems may not be powerful enough to scan these thicker products, we are already on path to development other systems that do.

“Crow’s goal is to continue to be the first place mills turn to for help with improving their operations. Traditionally this support has come from capital and maintenance project support. This acquisition, and the recent addition of PLC and electrical capabilities now allows us to help our clients in optimizing their operations. We are excited to have this opportunity with the AIC team and the 40+ years of experience they bring to the table!”

Hunter Wylie

Crow Engineering’s President