Posts Tagged ‘Plant Layout’

Factory Layout for Operational Excellence

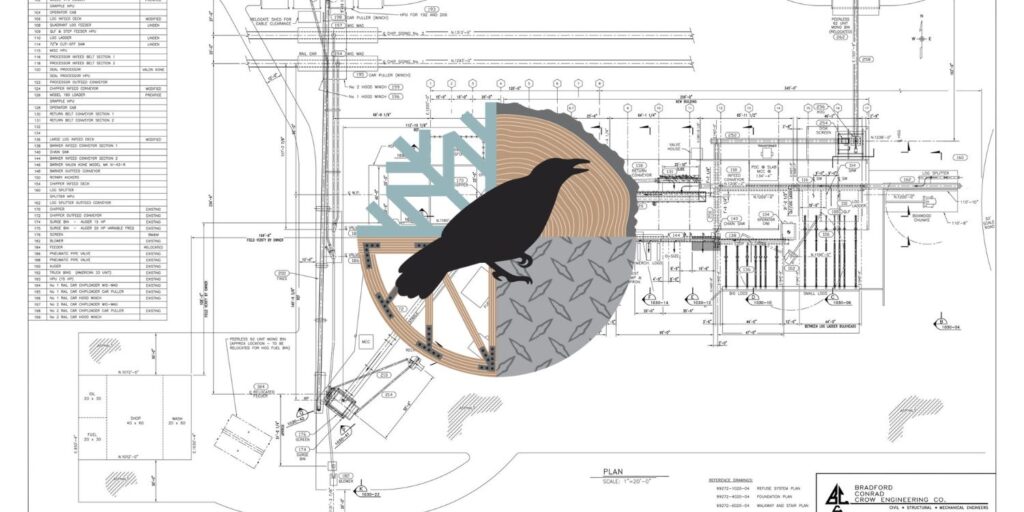

The Role of Factory Layout in Industrial Success Effective factory layout planning forms the foundation of streamlined workflows, increased productivity, and enhanced safety in industrial facilities. A thoughtfully designed layout optimizes every aspect of operations, from material handling to compliance with regulatory standards. Crow Engineering designs customized, optimized industrial plant layouts integrating cutting-edge automation technologies…

Read MoreDesigning a Factory: Optimizing Plant Layout and Production Lines

Designing a factory requires meticulous planning and industrial plant engineering to achieve efficient workflows, maximize space utilization, and seamlessly integrate production lines. Whether reconfiguring an existing layout, adding a new production line, or starting with a greenfield facility, thoughtful design is key to operational success and long-term efficiency. Importance of Plant Layout Optimization An optimized…

Read MorePlant Layout Engineering: Optimizing Industrial Spaces for Success

The Role of Plant Layout Engineering in Industrial Success Plant layout engineering is essential for facilities across various industries to achieve efficient and productive operations. Through effective plant layout engineering, businesses can achieve significant benefits, such as increased productivity, enhanced safety, and reduced operational costs. This process involves organizing workflows strategically, optimizing space utilization, and…

Read MoreIlluminating Success: The Critical Role of Industrial Lighting

The significance of industrial light engineering for proper lighting cannot be overstated when it comes to industrial and manufacturing settings. Unlike the ambient, decorative lighting that graces our homes, industrial lighting is engineered to meet the rigorous demands of environments like production facilities and warehouses where the risk of accidents and injuries is higher and…

Read MoreWhat is an Optimal Plant Layout Design?

Plant layout design is a critical factor in achieving manufacturing efficiency and profitability. It involves carefully planning and organizing the physical arrangement of machinery, equipment, workspaces, and materials within a manufacturing facility to maximize productivity, reduce waste, and enhance overall operational performance. An optimal plant layout is a key driver of success in today’s competitive…

Read MorePlant Layout Optimization Techniques: Enhancing Manufacturing Productivity

In today’s competitive business landscape, optimizing manufacturing processes is essential for companies to remain competitive, meet customer demands, and ensure profitability. One crucial aspect of achieving this optimization is the design and layout of industrial plants. A well-organized and efficient plant layout optimization can significantly impact productivity and overall operational success. The Significance of Industrial…

Read More