What Are VFD Packages?

A Variable Frequency Drive (VFD) package is a comprehensive solution that includes a VFD and all necessary components for its operation. VFDs regulate the speed and torque of electric motors by adjusting the frequency and voltage supplied to them. This precise control not only results in significant energy savings but also improves operational efficiency, enabling smoother, safer, and more reliable motor operation.

Custom VFD Packages for Enhanced Industrial Control and Efficiency

Precision and efficiency are key to maintaining a competitive edge in today’s industrial landscape. With Crow Engineering’s VFD solutions, businesses can expect seamless integration, precise control, and a robust approach to enhancing operational performance.

Importance in Industrial Automation

VFD packages are designed to simplify the integration of VFDs into industrial or commercial systems. These pre-configured and tested solutions minimize installation time and complexity, ensuring seamless operation and improved system performance. With VFDs in place, companies can easily adjust motor performance to match operational needs, thereby optimizing energy use and reducing wear and tear on equipment.

Benefits of VFD Packages

VFDs offer dynamic motor control to adjust motor speed dynamically by varying the frequency and voltage, leading to substantial energy savings. This is particularly useful in applications where motors don’t need to run at full speed continuously, such as HVAC systems or conveyor belts.

How VFD Control Improves Energy Efficiency in the Following Applications:

HVAC Systems: VFDs control the speed of fans and pumps, matching system demand and cutting down on energy consumption.

Pumping Stations: By regulating pump speeds to align with demand, VFDs optimize energy usage in municipal and industrial settings.

Conveyor Systems: VFDs manage the speed of conveyor belts, improving both throughput and energy efficiency.

- Adjustable Speed and Torque

VFDs provide precise control over motor speed and torque, which is essential for applications that require exact process control, such as in conveyors, extruders, and mixers. - Improved Quality Control

With enhanced control comes consistent product quality and reduced waste, optimizing overall process performance across various industries.

- Soft Start and Stop

VFDs reduce mechanical shock through gradual speed changes, lowering the risk of system failures. - Overload Protection

VFDs continuously monitor motor performance and offer overload and thermal protection, preventing damage and hazards. - Fault Detection and Diagnostics

With built-in diagnostics, VFDs help identify and address issues before they escalate into significant safety risks. - Reduced Electrical Hazards

By controlling inrush currents and optimizing operation, VFDs reduce the risk of electrical faults and overheating. - Emergency Shutdown and Safety Interlocks

VFDs can be integrated with emergency stop functions and safety interlocks to enhance overall operational safety.

Types of VFD Packages

Our standard VFD packages are tailored to meet specific control needs, offering seamless integration into existing systems. These packages ensure reliable motor control and energy efficiency across a range of industries.

Crow Engineering provides custom VFD solutions that are designed to fit your unique operational requirements. These solutions often involve housing VFDs in enclosures, simplifying installation, and minimizing cable runs.

Integrated VFD systems come with control systems that are pre-configured and tested before arriving on-site. This reduces startup and commissioning time, ensuring smooth integration into your existing operations.

Our mobile and modular VFD packages offer flexibility and ease of relocation. These skid-mounted systems are ideal for test systems or environments where equipment needs to be moved frequently.

VFD Packages for Many Industries

Manufacturing

VFD integration in manufacturing boosts productivity, reduces downtime, and cuts energy costs. Whether controlling conveyor belts or optimizing HVAC systems, VFDs are critical for enhancing efficiency.

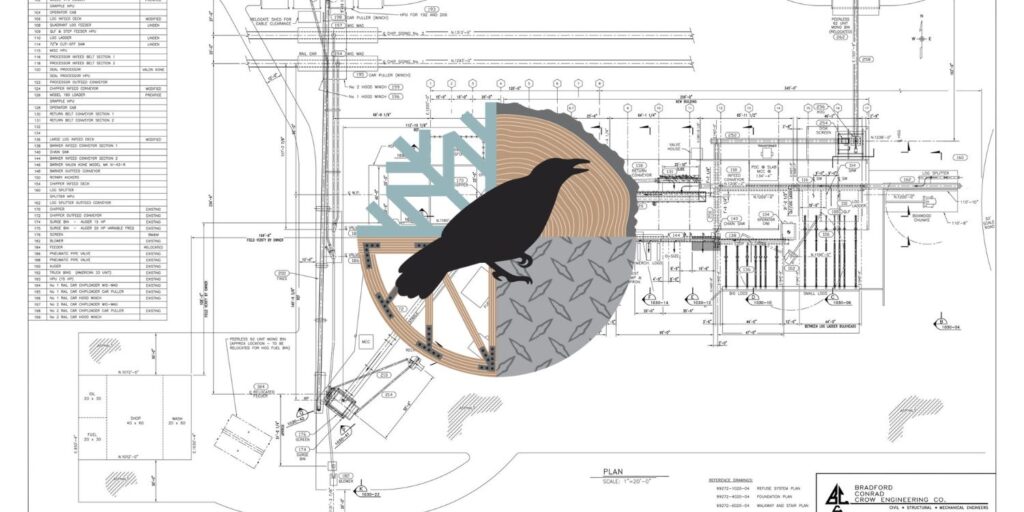

Forestry & Lumber

In lumber and forestry operations, VFDs provide precise control over sawmills and material handling processes, improving productivity while reducing energy consumption.

Utilities and Energy

VFDs are used extensively in utilities and energy industries to optimize the performance of pumps, fans, and compressors, leading to more efficient energy production and distribution.

Food & Beverage

Consistent quality control and precision in production processes are essential in the food and beverage industry. VFDs ensure that production lines run smoothly and efficiently, helping to maintain high product standards.

Mining & Heavy Industries

For mining and other heavy industries, VFD packages extend machinery lifespan, improve operational safety, and reduce the strain on critical equipment.

Why Choose Crow Engineering for VFD Packages?

Expertise in Custom Solutions

Crow Engineering’s extensive experience in providing tailored VFD solutions ensures that each system is designed to meet specific application requirements. We specialize in creating systems that optimize performance and efficiency for a wide range of industrial needs.

Advanced Technology and Integration

Using cutting-edge components from leading manufacturers, such as the Rockwell Automation VFD family, Crow Engineering supports a broad spectrum of equipment needs. Our advanced technology ensures seamless integration with existing control systems.

Comprehensive Support

We offer continuous support and consultation throughout the lifecycle of your VFD package. Our team is always available to address your industrial challenges, ensuring that your systems perform at peak efficiency over time.

Crow Engineering is committed to delivering reliable, energy-efficient VFD solutions tailored to your specific operational needs. Whether integrating VFDs into new systems or optimizing existing setups, our expertise guarantees enhanced performance, reduced energy costs, and improved process control. Contact us today to learn how Crow Engineering can support your VFD needs and boost your industrial efficiency.

the crow connection

Recent News

The Crow Connection delivers high-level insights on engineering, automation, and process optimization, helping you drive efficiency and innovation. Covering topics like AI-powered automation, manufacturing strategies, and industrial process improvements, it’s a must-read for leaders seeking a competitive edge.