Engineering & Design Services

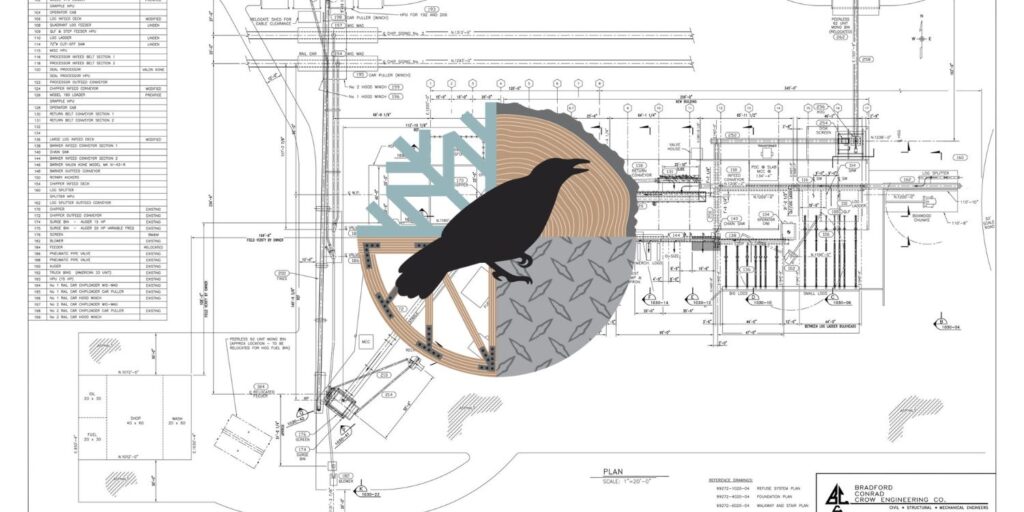

Equipment Configuration Goals- Infographic

Crow Engineering’s team offers custom equipment configurations, integration, automation, optimization, and installation support. Different equipment configuration options are provided in our initial feasibility studies to meet your project’s goals. Read More

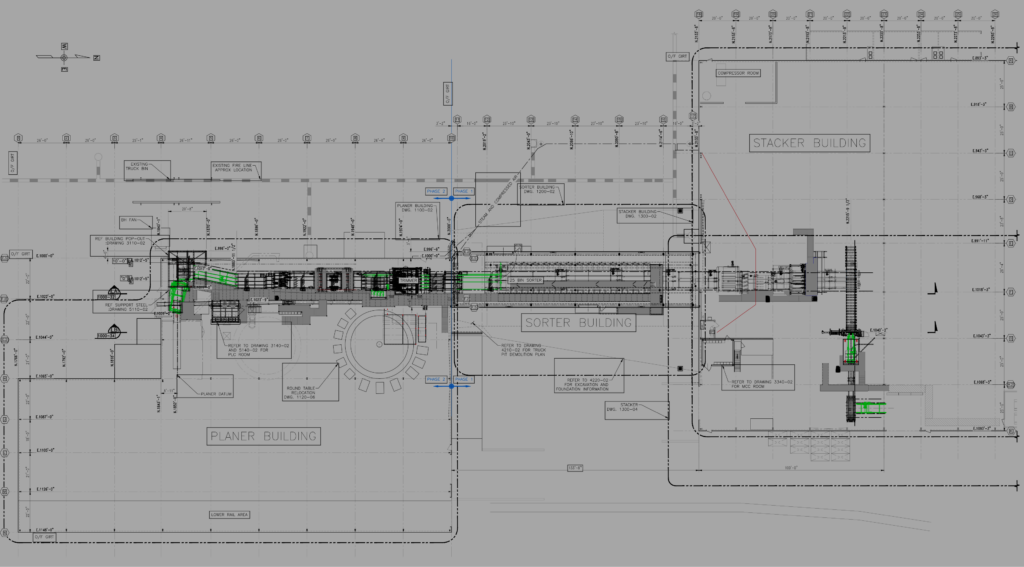

Read MoreDeveloping an Industrial Plant Layout- Infographic

In today’s competitive business landscape, optimizing manufacturing processes is essential for companies to stay competitive, meet customer demands, and ensure profitability. A key element in achieving this optimization is the design and layout of industrial plants. An organized and efficient plant layout can significantly enhance productivity and overall operational success. Read More

Read MoreTypes of 3D Scanning Technology: Pros & Cons

3D scanning technology is reshaping the way industries capture and utilize physical data, offering a bridge between the tangible world and digital analysis. 3D Scanning Aids Many Product and Process Improvements This transformative process analyzes real-world objects or environments to collect data on their shape and appearance, creating digital 3D models or “digital twins.” This…

Read MoreIlluminating Success: The Critical Role of Industrial Lighting

The significance of industrial light engineering for proper lighting cannot be overstated when it comes to industrial and manufacturing settings. Unlike the ambient, decorative lighting that graces our homes, industrial lighting is engineered to meet the rigorous demands of environments like production facilities and warehouses where the risk of accidents and injuries is higher and…

Read MoreThe Process of Achieving Optimal Plant Layout -Infographic

Plant layout design is a critical factor in achieving manufacturing efficiency and profitability. It involves carefully planning and organizing the physical arrangement of machinery, equipment, workspaces, and materials within a manufacturing facility to maximize productivity, reduce waste, and enhance overall operational performance. An optimal plant layout is a key driver of success in today’s competitive…

Read MoreTransforming Manufacturing Efficiency: Process Optimization Strategies

In the competitive landscape of modern manufacturing, optimizing a production process is not just an option—it’s a necessity for survival and growth. The goal of process optimization is to enhance efficiency, reduce waste, and increase productivity, thereby boosting profitability. However, achieving an optimized production process requires a strategic approach, incorporating advanced technologies, data analytics, and…

Read MoreGreenfield vs. Brownfield Projects: Navigating Complexities with Engineering Solutions

In the realm of engineering and construction, two terms frequently arise to categorize project types: greenfield and brownfield. Both concepts have distinct implications for project scope, challenges, opportunities, and strategies. Understanding the nuances between greenfield and brownfield projects is crucial for stakeholders to make informed decisions, tailor their approaches, and ultimately achieve their project objectives…

Read MoreWhat is an Optimal Plant Layout Design?

Plant layout design is a critical factor in achieving manufacturing efficiency and profitability. It involves carefully planning and organizing the physical arrangement of machinery, equipment, workspaces, and materials within a manufacturing facility to maximize productivity, reduce waste, and enhance overall operational performance. An optimal plant layout is a key driver of success in today’s competitive…

Read MorePlant Layout Optimization Techniques: Enhancing Manufacturing Productivity

In today’s competitive business landscape, optimizing manufacturing processes is essential for companies to remain competitive, meet customer demands, and ensure profitability. One crucial aspect of achieving this optimization is the design and layout of industrial plants. A well-organized and efficient plant layout optimization can significantly impact productivity and overall operational success. The Significance of Industrial…

Read More