News

Modernizing a Mill with 3D

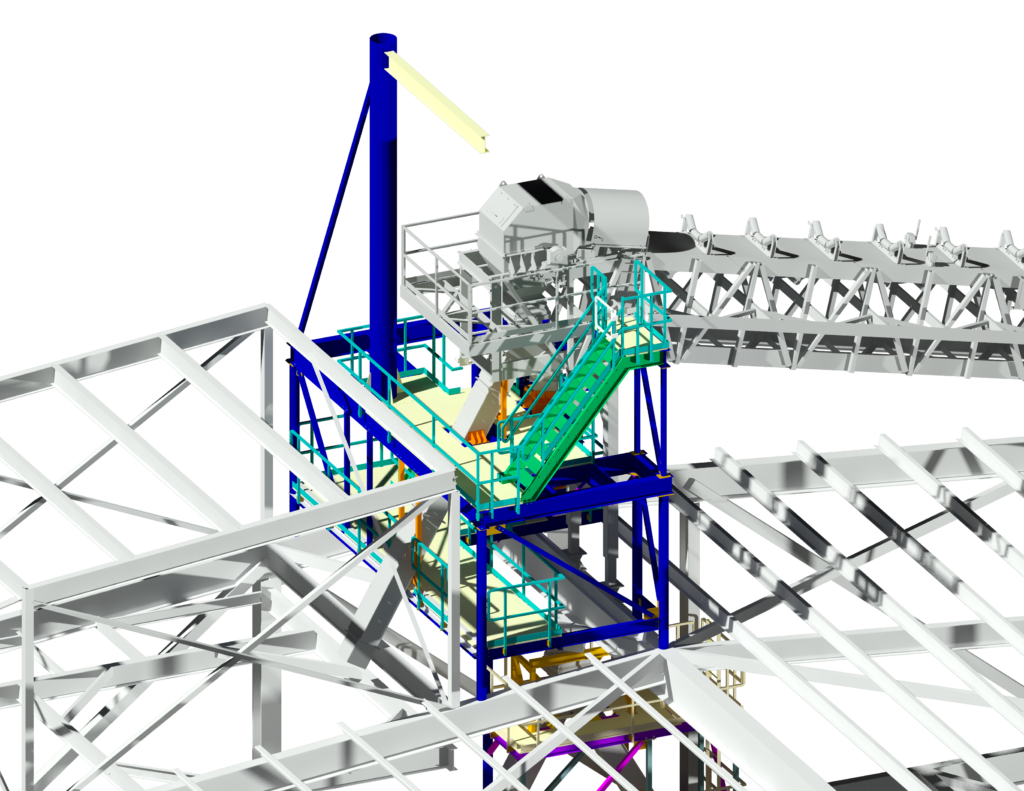

Recently, Crow Engineering completed an engineering design to replace a raw material infeed conveyor at a building products mill. The mill was connected to a mining operation with a single conveyor to deliver feedstock. The conveyor was built in 1962 and worn out. Any interruption or problems with this conveyor caused both mining and mill production to stop. The owner hired Crow to evaluate the situation and investigate possible solutions to replace, upgrade, or rebuild the raw material feed line.

Read MoreEquipment Relocation, and installation.

Recently, Crow was hired by a client in the Northwest that wanted to replace an outdated planer mill. The client had identified a planer line located in the Southeast and hired Crow as the principal consulting engineer and the contractor responsible for disassembling, relocating, adapting, and installing this system in their facility. To accomplish the task, Crow divided the project in several phases.

Read MoreNew Crow Engineering Southeast Office

This office has allowed us to significantly expand our Southeast presence and deepen our engineering and project management expertise. This commitment to the Southeast region has already greatly increased our ability to service both new and existing clients within the forestry and building products industries.

Read More