Advanced HMI Operating Systems for Enhanced Industrial Control

HMI operating systems are crucial for monitoring, controlling, and optimizing industrial processes, leading to improved operational efficiency and user experience. Crow Engineering specializes in providing advanced HMI machine interface solutions customized to meet the unique needs of various industries, ensuring seamless integration and optimal performance.

HMI Operating Systems Services

Crow Engineering offers custom human machine interface systems design and development including software and hardware integration.

- Custom HMI Design

We tailor HMI interfaces to meet specific client needs, ensuring intuitive and efficient user experiences. Our custom designs focus on user-friendly layouts and functionality that enhance productivity and reduce error rates. - Software Development

Crow Engineering develops robust HMI software solutions that integrate seamlessly with existing systems and processes. Software should be designed for reliability, scalability, and ease of use, ensuring that your operations run smoothly. - Hardware Integration

Ensuring seamless integration of HMI software with various hardware components and industrial equipment is critical. We develop top-tier control solutions, working with quality components such as Allen Bradley PLC control solutions from companies including Rockwell, known for quality automation systems. Our team excels in integrating HMI systems with a wide range of hardware to provide cohesive and efficient solutions.

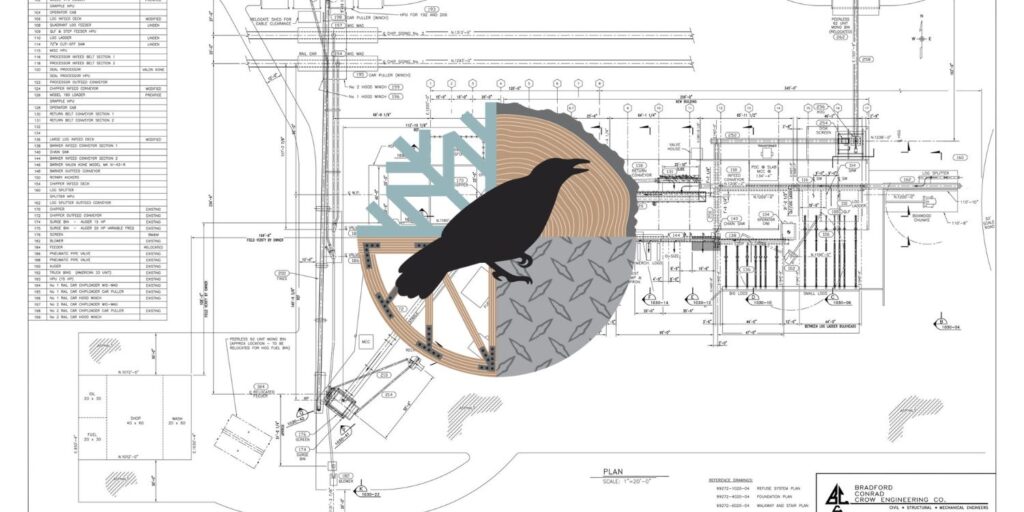

Custom Built Machine Control Engineering Solutions

Programmable Logic Control, PLC, and Historian systems are essential in the development of modern automation concepts. We offer system solutions with Rockwell Automation control systems for individual machines with or without human machine interface (HMI) as well as for networked plants with multiple control points.

Human Machine Interface Industry Applications

HMI solutions enhance productivity and efficiency in lumber and forestry operations by automating and streamlining processes such as milling and material handling. Advanced data visualization helps monitor machinery performance and maintain high output quality.

In manufacturing, HMI systems improve workflow management and process automation, leading to higher efficiency and reduced downtime. Custom dashboards provide real-time insights into production metrics.

For process industries like oil and gas, pharmaceuticals, and food and beverage, HMI systems enhance process control, ensure regulatory compliance, and improve safety by providing detailed monitoring and alarm management.

HMI solutions for utilities such as water treatment and power generation optimize the management and control of operations, ensuring reliable and efficient service delivery through advanced monitoring and remote access capabilities.

In the construction industry, HMI systems facilitate better project management and machinery operation, enhancing safety and operational efficiency by providing real-time data and alerts.

HMI systems in commercial and institutional settings improve building management by integrating systems for lighting, HVAC, and security, resulting in better energy efficiency and occupant comfort.

For distribution centers, HMI solutions streamline logistics and warehouse operations by optimizing material handling systems and improving inventory management through real-time data monitoring.

In the food and beverage industry, our HMI systems ensure consistent product quality and regulatory compliance by monitoring production processes and managing critical control points.

HMI systems enhance cold storage operations by maintaining precise temperature control and monitoring refrigeration systems to ensure the integrity of stored products.

In agriculture, HMI solutions automate irrigation, monitor crop health, and optimize resource usage, contributing to more efficient and sustainable farming practices.

For the chemical industry, HMI systems improve safety and process control by providing real-time monitoring and alarm management, ensuring compliance with stringent regulatory standards.

Crow Engineering offers comprehensive HMI operating systems services designed to enhance industrial control and improve operational efficiency. Our expertise in machine automation, custom design, development, and installation ensures that clients receive tailored solutions that meet their unique needs.

Installation and Configuration

Crow provides installation services to ensure that HMI operating systems are correctly configured and fully operational.

- Initial Setup

Our experts handle the entire setup process, from hardware installation to software configuration. - System Configuration

Customizing settings and parameters to optimize system performance and meet specific operational requirements is a key part of our service. We ensure that your human machine interface system is fine-tuned to deliver peak performance. - Testing and Validation

Thorough testing is conducted to verify that HMI systems function as intended and meet all performance criteria. This step is crucial to ensure reliability and efficiency in real-world operations.

User Training and Support

Crow engineers provide training for operators and maintenance personnel to ensure they can effectively use and manage HMI systems.

- Training Programs

Our training programs are designed to enhance user proficiency and confidence. - Documentation

Providing detailed manuals and user guides is part of our commitment to customer support. These documents assist with system operation and troubleshooting, ensuring that your team has the information they need at their fingertips. - Ongoing Support

We offer continuous support services, including troubleshooting, updates, and system enhancements. Our support team is always available to help you maintain optimal system performance.

Data Visualization & Analytics

Implementing HMI systems that provide real-time data visualization enhances monitoring and decision-making processes.

- Real-time Monitoring

HMI systems should allow operators to view critical data in real-time, facilitating prompt and informed decisions. - Historical Data Analysis

HMI solutions enable the collection and analysis of historical data to identify trends and improve operational efficiency. This capability is essential for long-term planning and optimization. - Custom Dashboards

Custom control system dashboards that display key performance indicators (KPIs) and other critical data in an easily understandable format. These dashboards are tailored to meet the specific needs of your operation, providing clear and actionable insights.

Advanced Features & Capabilities

Crow Engineers provides integrated control solutions and advanced control system management features to ensure remote access, alarm, and security features.

- Remote Access

Our solutions allow for remote monitoring and control of HMI systems, increasing flexibility and responsiveness. This feature is particularly valuable for operations that require constant oversight. - Alarm Management

Timely notifications of events and issues are critical. Effective alarm management helps prevent downtime and enhances operational safety. - Security Features

Incorporating robust security measures to protect HMI systems from unauthorized access and cyber threats is a top priority. Our security solutions safeguard your systems and data, ensuring continuous and secure operations.

the crow connection

Recent News

The Crow Connection delivers high-level insights on engineering, automation, and process optimization, helping you drive efficiency and innovation. Covering topics like AI-powered automation, manufacturing strategies, and industrial process improvements, it’s a must-read for leaders seeking a competitive edge.