Simple System

Easy to Deploy

Reduces Labor

Improve Performance

PROCESS SENTINELS

Control Processes Like Never Before

A flexible Artificial Intelligence (AI) and sensor system which can be deployed at any industrial process step to see and predict objects and events, recommend actions and report on important metrics. It’s AI can be trained to make human-like decisions consistently and quickly.

Applications for Process Sentinels

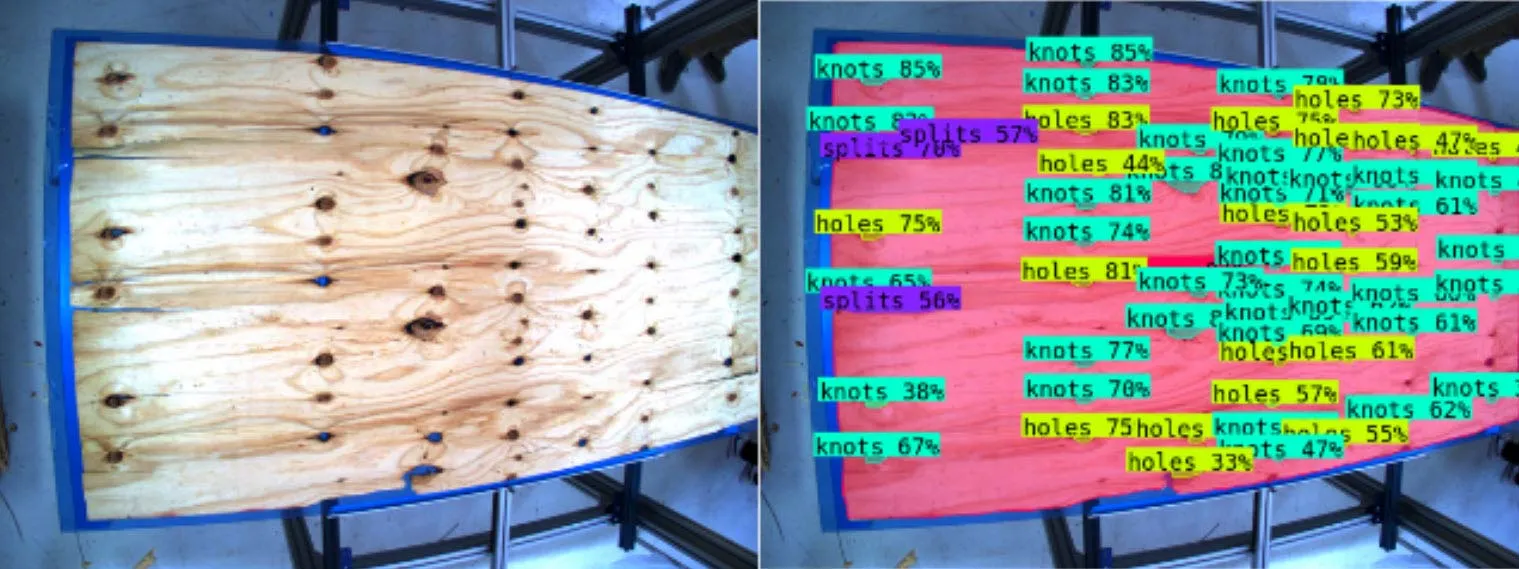

Process Sentinels provide analytics and reporting back to Mill operations staff to track key metrics for their products. Leveraging computer vision, the agent in this example is counting veneer panels and the number of knots, holes, splits.

| Process Step | AI Vision Target(s) | Potential Automation | Value |

| Trim saw outfeed | Skew, double lug | Notification, stop, slow, robotic fix | Better quality outfeed, prevent jams in conveyance to round table/grader… |

| Stick separator | Stick full length without broken ends | Notification, robotic fix | More efficient and effective separation |

| Location | AI Vision Target(s) | Potential Automation | Value |

| Log Singulation | Doubles | Notify, Stop, Fix | Reduced costs due to doubles |

| Lathe Infeed | Lathe tender | Notify, Stop, Slow, Fix | Eliminate or reduce lathe tendre labor |

| Clipper/Chipper Infeed | Wad management | Slow, Fix | Eliminate downtime at machine centers clearing jams |

| Dryer Infeed | Loader misfeed | Identify, Fix | Eliminate Headcount at Dryer Infeed |

| Dryer Outfeed | Multi sheet stack to grader | Notify, Stop, Fix | Clear doubles, wads off dryer infeed prior to entry into grade line. Eliminate headcount at 90 degree turns. |

| Core/99” Saw Infeed | Load correction | Stop | Prevent Core saws from being loaded incorrectly |

| Sander | Skips, mars | Notify | Identify line management of sander related defects |

| Package Quality | Quality issue detection and action | Notify | Reduced quality labor, increased value |

| Unauthorized entry | Access by people | Notify, Stop | More secure and safe environment, reduced incidents |

| Stock monitoring | stock levels | Notify, lockdown | Better stock control |

| Location | AI Vision Target(s) | Potential Automation | Value |

| Log Singulation | Doubles | Notify, Stop, Fix | Reduced costs due to doubles |

| Lathe Infeed | Lathe tender | Notify, Stop, Slow, Fix | Eliminate or reduce lathe tendre labor |

| Clipper/Chipper Infeed | Wad management | Slow, Fix | Eliminate downtime at machine centers clearing jams |

| Dryer Infeed | Loader misfeed | Identify, Fix | Eliminate Headcount at Dryer Infeed |

| Dryer Outfeed | Multi sheet stack to grader | Notify, Stop, Fix | Clear doubles, wads off dryer infeed prior to entry into grade line. Eliminate headcount at 90 degree turns. |

| Core/99” Saw Infeed | Load correction | Stop | Prevent Core saws from being loaded incorrectly |

| Sander | Skips, mars | Notify | Identify line management of sander related defects |

| Package Quality | Quality issue detection and action | Notify | Reduced quality labor, increased value |

| Unauthorized entry | Access by people | Notify, Stop | More secure and safe environment, reduced incidents |

| Stock monitoring | stock levels | Notify, lockdown | Better stock control |

| Location | AI Vision Target(s) | Potential Automation | Value |

| Log grappling from pond | Anomalous logs Log grappling quality/incidents | Notify of anomalous logs Grappling guidance Grappling automation | Less downtime, higher quality due to better anomalous log handling |

| Debarker infeed | Anomalous logs Empties/doubles | Notify problems for human intervention Slow/stop line before incident Robotic intervention | Reduced oversight labor Fewer incidents, more uptime, less maintenance Higher quality and more consistent input |

| Forming line | Contamination | Notify operator of potential incident Stop before incident | More uptime, lower maintenance costs due to fewer and less severe incidents |

| Hot press | Jam or default movement of carger | Notify operator Stop before incident | More uptime, lower maintenance costs due to fewer and less severe incidents |

| Plant outfeed | Product quality | Notify operators of quality issues Signal operators/machines earlier in process of issues in real time for action Robotic handling of quality issues | Increased quality and reliability of output due to enhanced feedback Lower costs due to quality issues due to same |

| Location | AI Vision Target(s) | Potential Automation | Value |

| Moulder | Saw performance, quality of input & output wood material |

Notify operators Stop for maintenance Auto-mark moulding and accounting |

Better preventative saw maintenance, less waste. Less skilled labor needed to manage outfeed |

| Rip Saw | Saw performance, labor performance |

Notify/stop for maintenance Outfeed sortation |

Increased quality and better maintenance. Reduced labor required per board processed. |

| Unauthorized entry | Access by people | Notify, Stop | More secure and safe environment, reduced incidents |

| Stock monitoring | stock levels per storage location | Notify, lockdown, inventory | Better stock control |

| Process Step | AI Vision Target(s) | Potential Automation | Value |

| Pack to box | Label quality, expiration date, lot code | Notification, stop, slow, robotic fix | Prevent products with damaged labels or missing expiration dates from being shipped to customer |

| Pack to thermoformer | Food product fit into package | Notification, stop, slow, robotic fix | Prevent air leaks that can lead to spoilage of food product |

| Process Step | AI Vision Target(s) | Potential Automation | Value |

| Queing for palletizing | Box integrity | Notification, stop, slow, robotic fix | Prevent damaged goods from being shipped to customer |

| Crate cleaning | Crate integrity inspection | Notification, stop, slow, robotic fix | Prevent damaged crates from being used which could damage product. |

0

KNOTS

0

SPLITS

0

HOLES

0

VENEERthe crow connection

Recent News

The Crow Connection delivers high-level insights on engineering, automation, and process optimization, helping you drive efficiency and innovation. Covering topics like AI-powered automation, manufacturing strategies, and industrial process improvements, it’s a must-read for leaders seeking a competitive edge.