Feasibility Study Analysis

Feasibility studies are your way to vet the capital requirements, headcount, financial returns, and jurisdictional requirements to determine the viability of a project. They are essential tools used by organizations to make informed decisions about your expected profits, return on capital, and ongoing costs of goods.

Understanding Feasibility Studies

Feasibility studies are not one-size-fits-all; rather, they are tailored to meet the unique requirements of each project. The scope and complexity of a feasibility study can vary significantly based on the nature of the project and the operational demands it entails. For larger or more intricate projects, multiple feasibility studies may be necessary, each with distinct requirements aligned with the project’s objectives and organization type.

Feasibility Study for Construction Projects

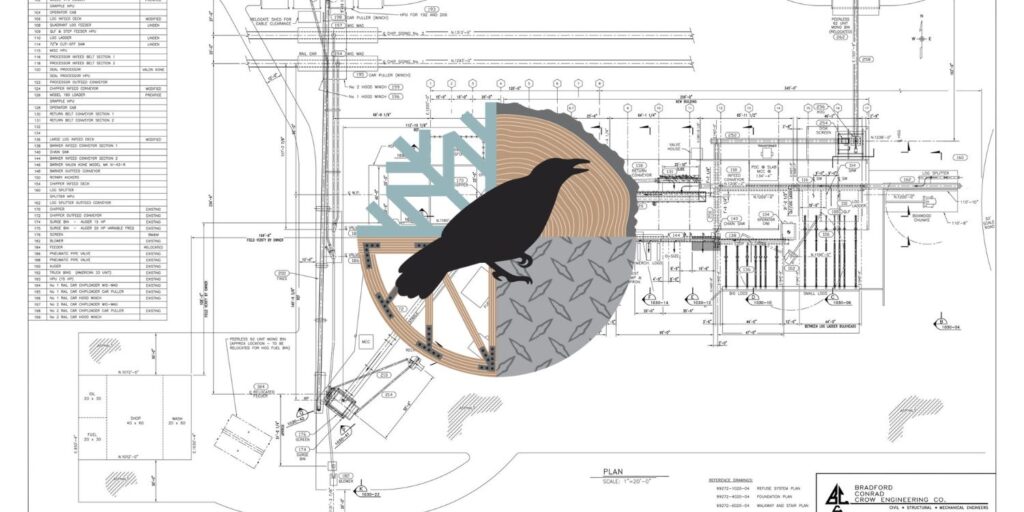

Construction projects often require meticulous planning and assessment to ensure their successful execution. A feasibility study for plant modernizations, also known as a feasibility analysis or viability study, plays a pivotal role in the early stages of project development. At Crow Engineering, we specialize in conducting comprehensive feasibility studies for construction projects to address uncertainties and challenges associated with project planning.

Key Objectives of a Construction Feasibility Study

Our well-designed and structured construction feasibility studies aim to provide valuable insights into the project’s potential success. Some of the crucial aspects we evaluate include:

- Capital Requirements: We can estimate the amount of capital required per modernization option.

- Site Analysis: Identifying and addressing any site-related issues or opportunities that may impact capital or shutdown requirements.

- Risk Assessment: Providing risk-based analysis into each modernization option. Risks include expected shutdown times, incorporation of new technology/vendors, and schedule/timeline delays.

At Crow Engineering, we prioritize a thorough and detailed assessment to guide your construction project toward success.

Our comprehensive feasibility analysis studies may include assessments of additional factors, such as:

Working with your local permitting authorities to determine what requirements must be met to complete the modernization.

Starting the process to identify and mitigate site safety and hazard issues.

We work with our clients to provide them with the best opportunity to stay in direct control of the vendor/equipment partners. We also provide alternate options to turnkey site projects that allow clients to purchase directly from vendors, eliminating excessive contractor markups.

Throughout the planning process, we will identify key staffing positions and are able to forecast your headcount/shift needs for the facility post-modernization.

Feasibility Study for Industrial Plant Layout and Optimization

Manufacturing plants require careful planning and optimization to remain competitive and efficient. Our feasibility analysis for industrial plant layout and optimization is designed to mitigate risks and enhance your project’s chances of success.

At Crow Engineering, we specialize in conducting thorough feasibility studies to help you make informed decisions regarding your industrial plant layout and optimization projects. The goal of feasibility studies is to allow organizations to make informed decisions about project implementation, whether considering a greenfield facility construction, plant renovation, a new product launch, or process optimization.

Crow Engineering offers more than 50 years of experience and a multi-faceted approach to feasibility analysis for successful project implementation that results in maximum return on investment (ROI). Contact us today to ensure your company makes informed decisions that result in improved efficiency, productivity, and profitability based on meticulously developed feasibility studies.

Our feasibility study analysis entails:

Determining whether refurbishing or upgrading existing equipment or acquiring new equipment is the best approach to meet manufacturing needs.

Analyzing your current maintenance requirements and working to reduce unplanned maintenance tasks.

Evaluating the impact of adding new product lines on market share and current operations.

Assessing options for moving production lines, both intra-plant and inter-plant, to improve operational efficiency.

Comparing conventional warehousing with automated storage and retrieval systems (ASRS) to maximize space and efficiency.

Focusing on asset optimization to maximize income generation and asset productivity.

the crow connection

Recent News

The Crow Connection delivers high-level insights on engineering, automation, and process optimization, helping you drive efficiency and innovation. Covering topics like AI-powered automation, manufacturing strategies, and industrial process improvements, it’s a must-read for leaders seeking a competitive edge.