What Are Safety Evaluations?

The primary objective of safety evaluations is to systematically identify potential hazards within an industrial setting, assess the associated risks, and ensure that all products, processes, and operations comply with relevant safety regulations and standards. These evaluations are essential for creating a safe working environment and preventing accidents that could harm employees, damage equipment, or disrupt production. Safety evaluations involve a thorough examination of all aspects of a facility’s operations, from machinery and processes to employee practices and environmental factors. By identifying and mitigating risks, safety evaluations help maintain a secure and compliant workplace, ultimately contributing to the overall efficiency and sustainability of industrial operations.

Process

Key Steps in Safety Evaluations

Safety evaluations are systematic processes that involve several critical steps to ensure that potential hazards are identified and managed effectively within industrial and manufacturing environments. The typical steps include:

This initial step involves recognizing potential sources of harm in the workplace. Hazards can arise from various factors, such as machinery, chemicals, environmental conditions, or even human behavior. Identifying these hazards early is essential for preventing accidents and ensuring the safety of all personnel.

Once hazards are identified, the next step is to evaluate the likelihood and severity of adverse effects associated with these hazards. Risk assessment involves analyzing the potential impact of each hazard on workers, equipment, and the environment. This step is crucial for prioritizing risks and determining the appropriate mitigation strategies.

In this phase, the focus is on determining the extent to which individuals or the environment may be exposed to the identified hazards. This assessment considers factors such as frequency, duration, and intensity of exposure, helping to understand the potential health and safety impacts.

The final step in the process is to integrate the information gathered from hazard identification, risk assessment, and exposure assessment. This step provides an overall picture of the risk associated with each hazard, enabling decision-makers to implement effective control measures and safety protocols.

Continuous Monitoring, Re-evaluations, and Employee Input

Safety evaluations are not a one-time activity; they require ongoing monitoring and re-evaluation. As new data becomes available, or as products, processes, and regulations change, it is essential to continuously update safety assessments. This continuous monitoring ensures that safety measures remain effective and that any emerging risks are promptly addressed, thereby maintaining a safe working environment.

Stakeholder Involvement

Effective safety evaluations involve input from various stakeholders, including employees, management, and safety experts. Engaging different perspectives ensures that the evaluations are comprehensive and that all potential hazards are identified and addressed. Employees provide valuable insights into daily operations, while safety experts offer technical knowledge and regulatory guidance. Management’s involvement ensures that safety measures are aligned with organizational goals and resources. This collaborative approach is key to creating a culture of safety within the organization and ensuring the successful implementation of safety initiatives.

Benefits of Safety Evaluations

Regular safety evaluations are crucial in industrial and manufacturing environments for multiple reasons. They serve as a proactive approach to maintaining a safe workplace, protecting assets, and ensuring compliance with regulatory standards.

The key benefits include:

Safety evaluations play a vital role in preventing workplace accidents by identifying potential hazards and implementing measures to mitigate risks. By proactively addressing these risks, companies can significantly reduce the likelihood of incidents that could lead to injury, equipment damage, or operational downtime. This not only protects employees but also ensures the smooth and uninterrupted functioning of industrial operations.

Safety evaluations play a vital role in preventing workplace accidents by identifying potential hazards and implementing measures to mitigate risks. By proactively addressing these risks, companies can significantly reduce the likelihood of incidents that could lead to injury, equipment damage, or operational downtime. This not only protects employees but also ensures the smooth and uninterrupted functioning of industrial operations.

Through regular safety evaluations, companies can identify and address issues that could potentially disrupt operations. By mitigating risks and preventing accidents, businesses can maintain high levels of operational efficiency, avoiding costly downtime and ensuring that production processes continue without interruption. This leads to better productivity and overall organizational performance.

Adherence to safety regulations is a critical component of maintaining a legally compliant industrial operation. Regular safety evaluations help ensure that all aspects of the facility meet the necessary safety standards, thereby avoiding legal issues, fines, and potential shutdowns. Compliance with regulations also enhances the company’s reputation and trustworthiness in the industry, contributing to long-term success.

Safety evaluations are not only about protecting people but also about safeguarding the company’s assets. By identifying potential risks to machinery, equipment, and infrastructure, safety evaluations help prevent damage that could result in costly repairs or replacements. This ensures that the company’s investments are protected and that resources are used efficiently.

Regular safety evaluations are not just a regulatory requirement—they are a vital component of a robust and resilient industrial operation. They ensure the well-being of workers, protect company assets, maintain operational efficiency, and secure compliance with safety regulations, ultimately contributing to the overall success and sustainability of the business.

Types of Safety Evaluation Services

Risk Assessment and Hazard Identification

Identifying potential risks and hazards is a fundamental aspect of maintaining a safe industrial environment. Risk assessment and hazard identification are critical processes that involve recognizing potential sources of harm within a facility and evaluating the likelihood and severity of adverse effects. By thoroughly identifying these risks, companies can take proactive measures to prevent workplace accidents, protect employees, and ensure compliance with safety regulations.

Training employees in mandatory safety standards is crucial to effective risk management. This includes essential practices such as lockout/tagout procedures, which prevent the accidental startup of machinery during maintenance, and the proper use of personal protective equipment (PPE). Additionally, understanding and managing risks associated with bloodborne pathogens are vital for ensuring worker safety in environments where exposure is a concern. These practices help create a safer workplace by minimizing risks and ensuring that all employees are equipped to handle potential hazards.

Process Safety Management (PSM)

Process Safety Management (PSM) is a comprehensive framework designed to manage hazards associated with processes involving highly hazardous chemicals. PSM is critical for industries that handle dangerous substances, as it ensures that these processes are managed safely and effectively, minimizing the risk of catastrophic incidents.

PSM is particularly important in industries such as chemicals, oil and gas, and pharmaceuticals, where the handling of hazardous materials is commonplace. These sectors rely on PSM to control risks associated with the storage, use, and disposal of hazardous chemicals, ensuring that operations are conducted safely and in compliance with regulatory standards. Implementing PSM helps companies protect their employees, the environment, and their operations from potential hazards.

Machine Safety Assessments

Machine safety assessments are crucial for ensuring that all machinery within a facility meets established safety standards. These assessments involve evaluating machines to ensure they are equipped with proper safeguards, including safety circuit analysis and lockout/tagout procedures, which prevent accidents during maintenance or operation.

In manufacturing environments where heavy machinery is used, ensuring the safety of these machines is paramount. Machine safety assessments help identify potential hazards associated with equipment, ensuring that operators can work safely and that the machinery complies with industry regulations. These assessments contribute to the overall safety of the facility by preventing machinery-related accidents and maintaining operational integrity.

Compliance Audits

Compliance audits are essential for ensuring that industrial facilities adhere to relevant safety regulations and standards, including those set by OSHA, ISO, and ANSI. These audits involve a thorough examination of the facility’s safety practices and procedures to ensure they meet regulatory requirements.

Compliance audits are crucial in avoiding fines, legal issues, and ensuring worker safety through rigorous adherence to safety protocols. By conducting regular audits, companies can identify areas where they may fall short of regulatory standards and take corrective action to address these issues. This not only helps protect employees but also ensures that the company remains in good standing with regulatory authorities.

Safety Program Development

Developing a tailored safety program is essential for fostering a culture of safety within an organization. A well-structured safety program includes training, emergency response plans, and continuous safety improvements, all designed to enhance the overall safety of the workplace.

A structured safety program is vital for maintaining compliance and reducing the risk of accidents. By implementing comprehensive training programs, companies can ensure that all employees are aware of safety protocols and know how to respond in emergency situations. Continuous safety improvements help maintain a safe working environment by regularly updating safety practices to reflect new risks and regulatory changes.

Industries We Serve

At Crow Engineering, we are committed to delivering innovative, efficient, and cost-effective engineering and design solutions across a wide range of industries. Contact us today to discuss your project and discover how we can help you achieve your goals. Your success is our priority.

Safety evaluations in manufacturing are critical for ensuring the safety of production lines, machinery, and workers. Regular safety assessments help prevent accidents, reduce downtime, and maintain compliance with safety regulations, contributing to a safer and more efficient manufacturing environment.

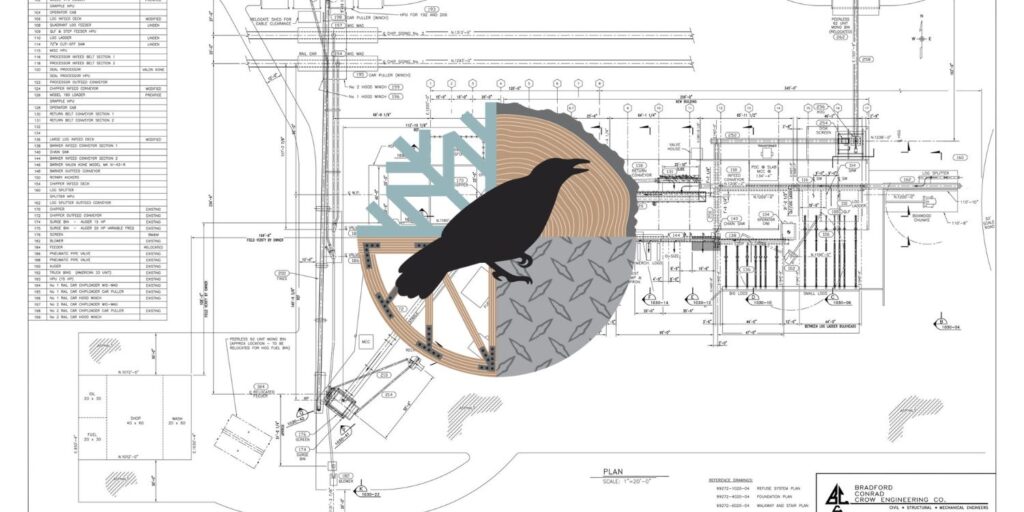

In the lumber and forestry industries, safety assessments are essential due to the heavy machinery and material handling involved. Evaluating safety practices in sawmills and other facilities helps prevent accidents, protect workers, and ensure that operations are conducted safely and efficiently.

Safety evaluations are vital in the utilities and energy sectors to prevent hazardous energy releases and ensure compliance with stringent safety standards. Regular assessments help protect workers and the environment, ensuring that these critical industries operate safely and reliably.

Safety evaluations on construction sites are crucial for protecting workers and ensuring compliance with industry regulations. These assessments focus on machinery safety, worker protection, and adherence to safety standards, helping to prevent accidents and maintain a safe construction environment.

Support Steel, Walkway, and Platform Design

- Crow Engineering excels in designing structural systems for chemical plants.

- Our solutions prioritize safety, functionality, and compliance with industry standards.

- Innovative engineering to support your chemical processing operations.

Civil Engineering Support

- Our civil engineering expertise includes site preparation and infrastructure design.

- We ensure the seamless integration of chemical facilities into their surroundings.

Process Equipment Integration

-

- We specialize in integrating process equipment into chemical plants, optimizing operations and efficiency.

- Precision engineering to streamline your chemical processing.

Process safety management and hazardous materials handling are critical in the chemical and pharmaceutical industries. Regular safety evaluations help manage the risks associated with these processes, ensuring that operations comply with regulatory standards and are conducted safely.

Why Choose Crow Engineering for Safety Evaluations?

Expertise and Experience

Crow Engineering brings extensive experience in conducting safety evaluations across various industries. Our team of experts ensures that clients receive the most comprehensive and accurate assessments, customized to the specific needs of their operations.

Comprehensive Approach

We use advanced tools, methodologies, and industry best practices in all our safety evaluations to deliver thorough and reliable results. Our comprehensive approach ensures that every aspect of safety is addressed, from hazard identification to risk management and regulatory compliance.

Continuous Support

Crow Engineering provides ongoing support and consultation services to help clients maintain high safety standards over time. Our commitment to continuous improvement ensures that safety remains a priority throughout the lifecycle of your facility, helping you adapt to new challenges and regulatory requirements as they arise.

Safety evaluations are essential to maintaining a secure, efficient, and compliant industrial operation. By partnering with Crow Engineering, you can ensure that your facility not only meets regulatory requirements but also operates at the highest standards of safety and efficiency. Our comprehensive safety evaluation services are tailored to your specific needs, ensuring that all potential risks are identified and mitigated. Contact Crow Engineering today to schedule a consultation and discover how our safety evaluations can benefit your operations, protect your workforce, and optimize your processes.

Crow Engineering offers expert design and engineering consulting services designed to enhance operational safety and compliance across various industries. We provide custom solutions to meet your specific needs, ensuring a safe and efficient workplace. Contact us today to learn how we can support your business with comprehensive safety evaluation services.

the crow connection

Recent News

The Crow Connection delivers high-level insights on engineering, automation, and process optimization, helping you drive efficiency and innovation. Covering topics like AI-powered automation, manufacturing strategies, and industrial process improvements, it’s a must-read for leaders seeking a competitive edge.