Tailored Solutions for Every Industry

Crow Engineering designs and implements custom conveyor and transfer systems for a wide range of industries. Our expertise ensures optimized material handling solutions that improve efficiency, enhance safety, and reduce operational costs.

Manufacturing & Industrial Facilities

Efficient production line material handling.

Forestry & Lumber Processing

Smooth log and timber transfer systems.

Energy & Recycling

Heavy-duty material transport for power plants and waste management.

Distribution & Warehousing

High-speed sorting and packaging solutions.

Agriculture & Food Processing

Sanitary and high-volume conveyor systems.

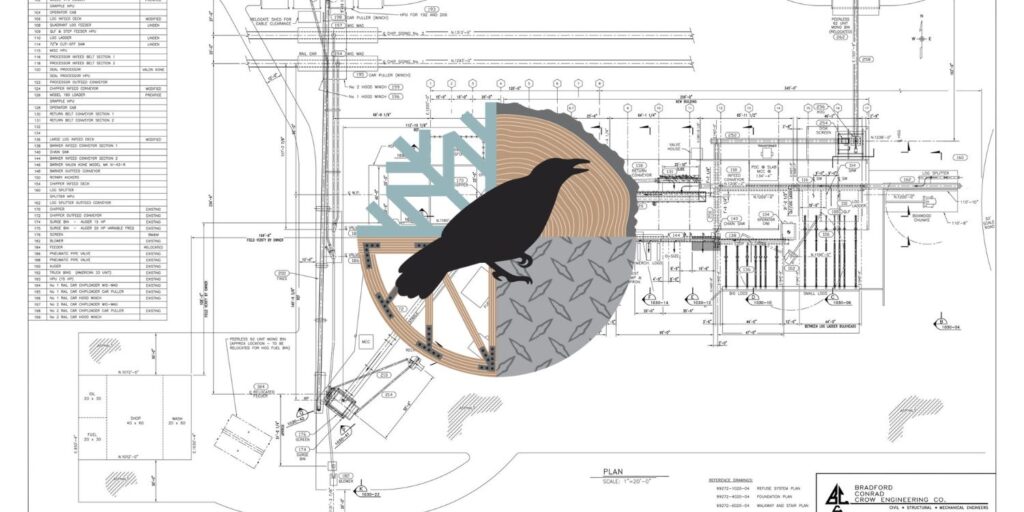

Conveyor Engineering Solutions for Industrial Efficiency

By integrating state-of-the-art conveyor engineering with automation technologies, Crow ensures reliable, efficient workflows that reduce the reliance on manual labor and improve overall production outcomes. From plant layout design to equipment configurations and the integration of AI solutions, we deliver customized solutions that drive productivity and accuracy in industries such as manufacturing, forestry, and cold storage.

Conveyor and transfer engineering is the design, implementation, and optimization of systems that automate material handling within industrial settings. There are different types of conveyors such as belt conveyors, roller conveyors, chain conveyors, and transfer stations. Each of these components works together to ensure smooth, efficient movement of materials through production lines, minimizing delays and manual intervention.

Key conveyor components include:

- Conveyor Belts: Used for transporting materials across distances.

- Transfer Systems: Enable the smooth transition of materials between different conveyor lines.

- Rollcase and Jump Rollcase Systems: Rollcase and jump rollcase systems are integral in the lumber and forestry industry, facilitating precise material movement and preventing jams in processing lines.

- Jump Chains: A critical tool for handling heavy logs or other materials, jump chains improve the efficiency and reliability of material movement in sawmills and manufacturing settings.

- Log Decks and Landing Tables:Designed to handle large loads like logs, these components are common in the forestry and wood products industries.

- Infeed Decks, Infeed Transfers and Outfeed Transfers: Ensure smooth transitions of materials in and out of conveyor systems, particularly in automated production environments.

- Automated Controls: Systems equipped with PLC controls, sensors, and cameras to monitor and manage material flow.

Applications of conveyor and transfer systems are essential across industries to streamline operations, reduce bottlenecks, and improve productivity.

Every facility has unique material handling needs, and a one-size-fits-all conveyor system simply won’t do. At Crow Engineering, we design and develop custom conveyor solutions tailored to the specific materials, workflows, and operational demands of your industry. Whether it’s belt conveyors for high-speed transport, chain conveyors for heavy-duty loads, or roller conveyors for smooth product movement, we engineer solutions that prioritize efficiency, durability, and seamless operation. Our designs account for factors like load capacity, environmental conditions, and integration with existing infrastructure to ensure long-term performance and reliability.

Facilitate precise material movement and prevent jams in processing lines.

For companies looking to enhance their existing material handling infrastructure, we specialize in seamless conveyor system integration and upgrades. Whether you’re adding new conveyors to an existing production line or upgrading outdated equipment for improved performance, our engineering team ensures a smooth transition with minimal downtime. We assess current workflows, identify bottlenecks, and implement smart automation, speed enhancements, and system optimizations to improve productivity. With Crow Engineering, you don’t just get an upgraded conveyor system—you get a strategically optimized material handling solution that enhances operational efficiency.

Our team integrates PLC-controlled conveyor systems to enable seamless, hands-free material transport with minimal manual intervention.

In today’s fast-paced industrial environments, automation is key to maximizing efficiency and precision. By incorporating AI-driven monitoring, sensor-based automation, and intelligent safety controls, we ensure that your conveyor system operates at peak efficiency while maintaining the highest safety standards. From automated sorting and product tracking to load distribution and quality control, our automation solutions help businesses reduce human error, improve workflow accuracy, and cut down on operational costs.

Even the best conveyor systems require ongoing maintenance to operate efficiently over time.

Crow Engineering provides comprehensive maintenance and support services to help businesses reduce downtime, extend equipment lifespan, and ensure continuous productivity. Our preventative maintenance programs are designed to identify potential issues before they become major problems, while our engineering assessments and troubleshooting services provide fast and effective solutions for any system malfunctions. Whether you need routine inspections, emergency repairs, or long-term performance optimization, our team is ready to keep your material handling systems running smoothly.

Control Everything

Systems equipped with PLC controls, sensors, and cameras to monitor and manage material flow.

Benefits of Transfer and Conveyor Engineering

Increased Productivity

Custom conveyor systems are designed to optimize workflow by reducing manual handling and ensuring smooth material flow throughout production lines. By minimizing production delays, Crow Engineering’s conveyor solutions enable industries to meet higher production targets with increased efficiency.

Cost Efficiency

Automated material handling systems help reduce labor costs by minimizing the need for manual labor. Additionally, energy-efficient designs reduce operational expenses by optimizing the use of equipment.

Improved Safety

Automated conveyors and transfer systems are designed to reduce workplace accidents by minimizing manual lifting and handling. Safety interlocks and automated shutdown features further enhance worker safety.

Enhanced Process Control

Advanced conveyor systems equipped with cameras, sensors, and automated controls allow real-time monitoring of materials, providing greater process visibility and enabling quick, data-driven decisions.

Advanced Engineering for Seamless Operations

Applications of conveyor and transfer systems are essential across industries to streamline operations, reduce bottlenecks, and improve productivity.

Types of Conveyor and Transfer Systems

Engineered for strength, durability, and material-specific applications.

Designed for efficient material movement and reduced manual handling.

Ideal for heavy loads and harsh industrial environments.

Precision control over material flow and product sorting.

Integrated IoT sensors for real-time tracking and efficiency monitoring.

Why Choose Crow Engineering for Conveyor and Transfer Systems?

Expertise Across Industries

With decades of experience in providing custom material handling systems for industries such as wood products, cold storage, agriculture, and manufacturing, Crow Engineering offers solutions designed to meet your specific operational needs.

Innovative and Efficient Solutions

We combine advanced automation technologies with conveyor engineering and design that maximize efficiency, scalability, and safety. We partner with experts in AI and robotics offering our clients the benefits of utilizing the latest technology.

Comprehensive Support

From initial consultation to post-installation support, Crow Engineering offers turnkey plant layout and automation services to ensure your conveyor systems operate at optimal levels.

Crow Engineering delivers innovative conveyor and transfer system solutions to enhance efficiency and safety across various industries. With decades of experience, we provide comprehensive plant and process optimization services from system design to full integration with automation technologies like PLC controls and HMI systems. Contact Crow Engineering today to optimize your material handling processes and improve operational performance with custom conveyor engineering.

the crow connection

Recent News

The Crow Connection delivers high-level insights on engineering, automation, and process optimization, helping you drive efficiency and innovation. Covering topics like AI-powered automation, manufacturing strategies, and industrial process improvements, it’s a must-read for leaders seeking a competitive edge.