Tailored Fabrication for Every Sector

At Crow Engineering, we provide custom metal fabrication solutions to a wide range of industries. Our expertise ensures that every product is engineered for optimal performance, longevity, and efficiency.

Manufacturing & Industrial Facilities

We fabricate custom conveyor systems, platforms, and machinery to streamline production lines, optimize material movement, and support automation for increased efficiency.

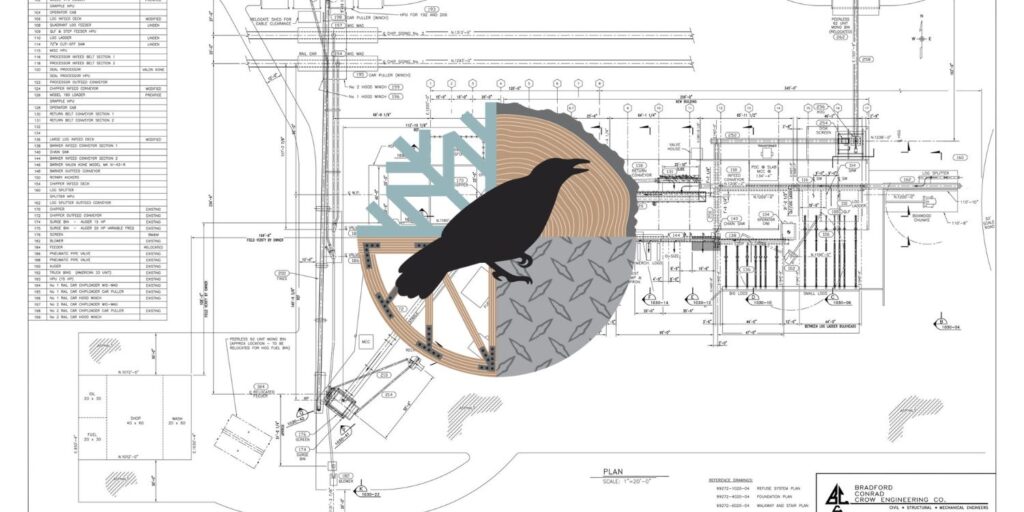

Forestry & Lumber Processing

Specializing in sawmill and log-handling equipment, we fabricate log decks, roll cases, and infeed transfers to ensure smooth, efficient operations, with options for automation integration.

Distribution & Warehousing

Our conveyor systems, platforms, and sorting equipment optimize order fulfillment and shipping processes, improving efficiency and reducing labor costs.

Cold Storage & Warehousing

We design racking systems, transport solutions, and steel frameworks to optimize temperature-controlled storage while ensuring compliance and safety.

Agriculture & Food Processing

We fabricate custom conveyors and platforms for sorting, processing, and storage, improving crop transportation efficiency while minimizing damage.

Chemical & Energy

We manufacture heavy-duty steel structures and specialized components for chemical plants and energy facilities, designed to withstand high-demand environments.

Construction & Industrial

Our structural steel supports, platforms, and process components enhance large-scale industrial operations, prioritizing strength, safety, and durability.

Our Services

Comprehensive Metal Fabrication Solutions

Crow Engineering delivers precision-engineered custom metal fabrication for industries requiring durable, high-performance solutions. From design to fabrication and finishing, we create custom conveyors, structural components, and welded assemblies tailored to operational needs. Our expertise ensures seamless integration, improved efficiency, and long-term reliability. Whether for manufacturing, construction, forestry, or energy, we provide cost-effective, high-quality solutions that enhance workflow and safety.

Custom metal fabrication is the process of designing and producing specialized components, structures, and equipment for industrial operations. This includes detailed designs, material selection, welding, machining, assembly, and installation to create products like conveyors, platforms, and steel frameworks that suit specific operational needs.

Crow Engineering excels in custom fabrication design and construction and offers flexible options. We can create your custom metal fabrication designs or work with client-provided designs for fabrication by our team or another fabrication partner. Our flexible approach ensures each solution is adapted to your particular challenges and company needs.

Every project starts with a detailed design and engineering phase, where our experts use advanced CAD software to create precise blueprints for custom metal components. We ensure that each design meets industry regulations, performance standards, and structural integrity requirements.

Choosing the right metal is crucial for durability and efficiency. We assist in selecting steel, aluminum, stainless steel, and specialty alloys, ensuring that your project benefits from optimal strength, corrosion resistance, and longevity.

Using high-precision cutting technology, we shape metals with laser cutting, plasma cutting, and CNC machining. Our forming capabilities, including bending, rolling, and stamping, allow us to create complex shapes and custom configurations with tight tolerances.

Our certified welders use MIG, TIG, and arc welding techniques to ensure high-strength, seamless joins. Whether it’s structural welding, custom brackets, or heavy-duty metal components, we guarantee precision, durability, and compliance with industry standards.

We provide surface treatments such as powder coating, galvanizing, anodizing, and painting to enhance corrosion resistance, durability, and aesthetics. Our finishing process ensures that your fabricated components withstand harsh environments and extended use.

We use high-quality carbon steel, stainless steel, and aluminum materials for custom metal parts fabrication and only quality plastics, polyurethane, and other substances for all fabrication projects. We ensure that your equipment meets your industry’s operational and environmental demands.

From belt conveyors to roll cases, chain conveyors, and sub-steel for various applications, Crow Engineering designs and fabricates custom equipment that integrates seamlessly into your industrial setup. Whether you need a new conveyor system or structural supports, our team ensures the end product is both functional and durable.

Crow offers custom metal fabrication services from a team of experienced welders, providing structural welding and assembly services at our facility or on-site, depending on your project’s requirements. This flexibility ensures timely installation and optimal performance, minimizing downtime and disruptions.

Crow manages all aspects of material procurement and shipping logistics. We have strong relationships with trusted vendors, allowing us to source materials at competitive prices while ensuring timely delivery and efficient lead times.

Core Components of Custom Fabrication Services

Crow’s custom fabrication services involve multiple critical components that ensure the successful implementation of your project.

Benefits of Custom Metal Fabrication by Crow Engineering

Crow’s custom fabrication services involve multiple critical components that ensure the successful implementation of your project.

Custom Solutions for Unique Challenges

Our ability to design and fabricate components that meet industry-specific challenges ensures operational efficiency. Whether you need pellet breakers, chain conveyors, or platforms, we tailor each solution to your specific requirements.

Durability and Safety

By using premium materials and adhering to stringent safety standards, Crow ensures that fabricated components are designed for durability and safe operation in any industrial environment.

Optimized Production Processes

Crow’s custom fabrications streamline production processes by reducing downtime, increasing throughput, and improving overall system performance. When integrated with machine automation and PLC control systems, our designs enhance the operational flow of your facility.

Crow Engineering’s Approach to Fabrication Design

Crow Engineering offers a full turnkey solution for fabrication projects, providing end-to-end services from initial concept design to installation and commissioning. Our team works closely with clients to ensure that every step of the fabrication process meets project specifications and industry standards.

Full Turnkey Solutions

Crow’s experienced team handles everything from engineering design to on-site installation and commissioning, with full transparency and open client communication. We’ve completed numerous turnkey projects, including demolition and the setup of new equipment in various industries.

Client Collaboration

Our flexible approach allows us to collaborate with clients, whether we are designing from scratch or working from existing designs. We can take on projects of any scale, ensuring your fabricated components fit seamlessly into your overall system.

Advanced Fabrication Technologies

Crow seamlessly integrates advanced technologies like robotic automation and PLC controls in our fabrication services, helping clients maximize production efficiency while minimizing downtime.

Why Choose Crow Engineering for Custom Metal Fabrication?

Crow Engineering has extensive experience in custom metal fabrication across industries like manufacturing, lumber, cold storage, agriculture, and energy. We offer:

- Proven Expertise: Decades of experience in delivering reliable and innovative solutions.

- End-to-End Support: From design to procurement, fabrication, and installation, we manage every step of the process.

- Advanced Technologies: We utilize the latest equipment and automation solutions to enhance efficiency and precision in all fabrication projects.

Crow Engineering offers custom metal fabrication services designed to meet the unique needs of industries such as manufacturing, lumber, cold storage, agriculture, and others. We provide comprehensive solutions from design through installation. Contact Crow Engineering today to speak with an experienced professional about optimizing your industrial processes and improving operational efficiency with experienced custom metal fabricators.

the crow connection

Recent News

The Crow Connection delivers high-level insights on engineering, automation, and process optimization, helping you drive efficiency and innovation. Covering topics like AI-powered automation, manufacturing strategies, and industrial process improvements, it’s a must-read for leaders seeking a competitive edge.