Core Engineering Services

A facility that is optimized for maximum efficiency and throughput is able to meet production requirements with quality products delivered on time. An efficient plant layout contributes to increased productivity and profitability. This is proving more and more difficult for production plants across many industries due to a lack of staffing options or challenges to keep up with technological advances. Optimizing your facility, equipment, and production processes is critical to survive and thrive in any market.

- Concept Development

- Preliminary Process Design and Plant Layouts

- Capital Budgeting

- Labor Forecasting

- Operations and Production Forecasting

- Project Justification and ROI Analysis

- As-Built Drawing Development

- Full-Service Engineering – Equipment, structural, civil, and electrical design

- Project Management

- Vendor Procurement and Oversight

- Construction Engineering and Management

- Automating unsafe or difficult-to-staff positions

- Reducing process variability

- Re-design of equipment, controls, and utilities to eliminate reliability issues

- Material Handling Equipment: Transfers, Residuals, Conveyance

- Custom Saw Centers

- Modifications to Existing Equipment

Crow industrial process engineers possess vast experience in providing industrial plant engineering solutions that are focused on improving your bottom line.

We sit down with you to fully understand your current situation and what your goals are. We roll up our sleeves and walk through your plant to analyze your processes and challenges. We listen to your concerns and challenges to achieving your goals. We use as-built drawings if you have them, or our skilled process engineers can create them for you, to break down areas of opportunity that can be optimized.

Plant Layout Optimization Tools

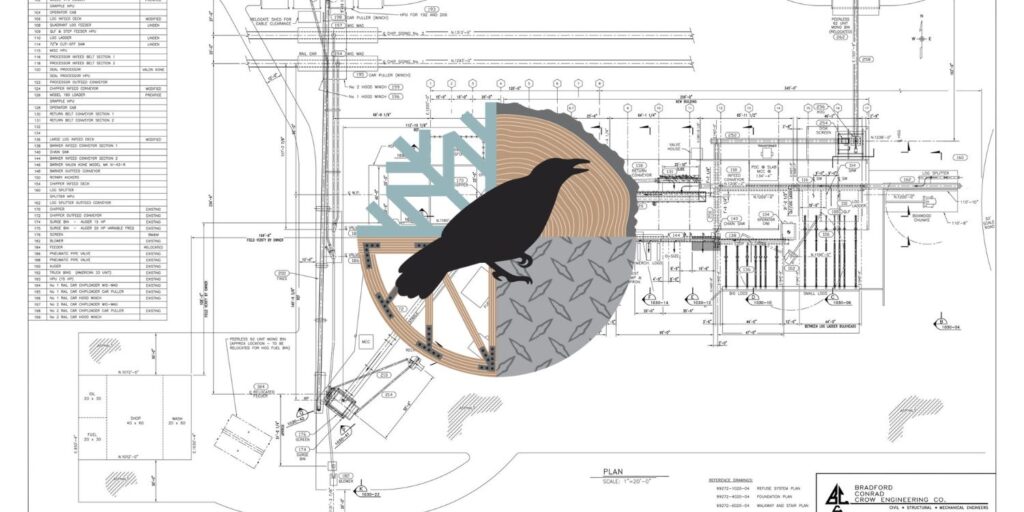

Crow Engineering utilizes the latest process engineering tools, including 2D and 3D drawings, Building Information Modeling (BIM) technology, 3D laser scanning, material flow analysis, and a variety of engineering components to provide the most advantageous plant layout scenarios.

We can analyze the energy efficiency of your plant operations and provide cost-saving solutions and product line enhancements. Crow has experience in conveyor and transfer engineering and design, machinery and equipment layouts, and product line enhancements.

Process and Equipment Improvements

Process Improvements and Technology Advances

Our plant layout optimization includes solutions for maximum productivity, staffing, manufacturing costs, and product recovery. Our engineers help companies realize the advantages of advanced technology and provide options for integrating new equipment to modernize plant operations.

Equipment Optimization

Crow analyzes your current equipment and alternative equipment configurations to provide Overall Equipment Effectiveness (OEE) improvement. Our team of engineers provides solutions for outdated equipment if you have maintenance issues due to obsolete parts or a lack of support.

Vendor and Material Management

Vendor Management

Crow process engineers have established working relationships with a multitude of vendors and contractors across North America to help deliver your project.

Material Flow and Material Handling Systems

Crow Engineering offers extensive experience in developing successful material handling systems for companies in the wood products and bulk handling industries. We specialize not only in the layout but the design of specific pieces of equipment to provide the most efficient flow of material.

Specialized Solutions and Expertise

Crow Engineering provides comprehensive plant layout optimization solutions for companies of all sizes with specialization in:

- Wood products

- Cold storage

- Warehousing

- Heavy industrial

- Food processing facilities

- Other commercial and industrial businesses

We offer more than 50 years of experience in modernizing plant processes to meet our client’s productivity and profitability goals. Contact us to take your operation to the next level and maximize your ROI from leaders in industrial plant engineering.

the crow connection

Recent News

The Crow Connection delivers high-level insights on engineering, automation, and process optimization, helping you drive efficiency and innovation. Covering topics like AI-powered automation, manufacturing strategies, and industrial process improvements, it’s a must-read for leaders seeking a competitive edge.