To ensure safety and minimize the risk of operational shutdowns at a time of high demand, many mills commission a structural assessment of critical facilities. Such assessments typically involve an analysis and evaluation of foundations, framings, and associated construction systems and details. The objective is to determine existing load capacity, identify structural deficiencies, and assess the causes and impacts of potential structural failures.

The extent of such an assessment depends on the condition and complexity of the resource examined, its current or intended use, and the amount of information available or attainable. But whatever the particular circumstances, mills want clear recommendations to correct structural deficiencies – or a new structural design with specific engineering solutions.

Expertise needed

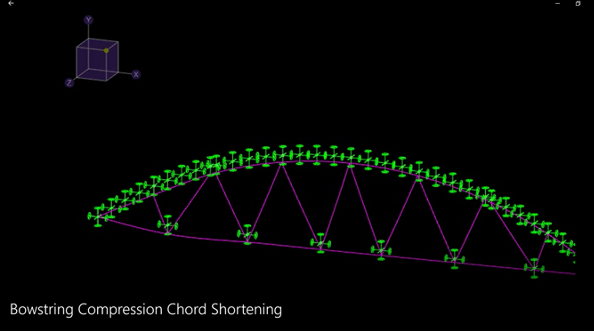

It’s important to investigate thoroughly and know what you’re looking for. For example, in a recent review for one customer, a Crow engineer investigated the performance and construction of bowstring trusses. What initially appeared to be a tension (bottom) chord failure was actually a symptom of a more serious issue: the failure of the compression (top) chord. READ MORE

Essentially, the top chord was compromised and shortened. This caused the more noticeable failure of the bottom chord.

Using an animation, our engineer, simulated on-site conditions and showed what would happen to the truss if the compression chord failed. The animation made it clear that as the compression chord failed, it shortened – causing the tension chord failure. While applying a tension chord splint would alleviate the secondary failure (bottom chord), it would also increase load to the compression chord and exacerbate the primary failure mechanism.

To ensure the safety of this truss chordcompression (top) chord needed to be supported. Critically, it was determined that supporting the truss through the bottom chord only (and only on one side of the shoring tower) would have increased the load in the web members, causing the failure of web members, shear plates, and strap plates. These conclusions led our engineer to recommend a shoring design to be put in place as soon as possible.

The three levels of a structural assessment

Structural assessments vary. Generally speaking, there are three varieties:

- Cursory Assessment

Visual overview of the general condition of the building envelope. It is often used for screening multiple buildings to establish priorities for maintenance and repair or further study. - Preliminary Assessment

Site visit to identify problem areas, review available documents, interview of involved parties, and generate a preliminary report of findings and recommendations. - Detailed Assessment

Review of documentation, component classification, field investigation, testing, analysis, and report.

Each assessment should be supplemented with a structural assessment report. Such a report looks at working conditions and makes recommendations for immediate and short-term repairs – all based on visual observation, measuring, video/photography, sampling, testing, analysis, and documentation depending on the level of the assessment.

Faulty construction, unsafe structural conditions for gravity and wind/snow loads, substantial structural damage due to deterioration – all of these can be identified with a structural assessment. Addressing these issues can help prevent further facility damage, collapse, equipment loss or damage, and – most importantly – accidents and fatalities.

Do you have structural questions? Call (503) 213-2013 or email Crow info@crowengineering.com to schedule a consultation. Our registered Professional Engineers (PE) can provide a structural assessment and report to evaluate your structural conditions and needs.

Who are we?

Crow Engineering is a multi-discipline consulting engineering firm serving mechanical, structural, and civil engineering needs for a variety of industries.

Engineering Services

the crow connection

Recent News

The Crow Connection delivers high-level insights on engineering, automation, and process optimization, helping you drive efficiency and innovation. Covering topics like AI-powered automation, manufacturing strategies, and industrial process improvements, it’s a must-read for leaders seeking a competitive edge.