At Crow, one of our core goals is to be the first place mills turn when they want to improve their operations Traditionally, we’ve pursued this goal by supporting our clients through capital projects and maintenance services. But recently, we’ve expanded our capabilities to include custom fabrication — a craft that demands more than just advanced machines for bending, forming, and cutting. It requires the hands and minds of skilled people.

That’s why we’re especially proud to have welcomed a team of talented professionals with deep experience in fabrication to the Crow family.

If you are looking for a metal fabricator, you might want to learn from our own acquisition experience. Here are three key points to consider to make sure your fabricator can deliver the value you expect.

1. Equipment and materials

Does your fabricator have top-of-the-line equipment such as welders, millers, and CNC machines? And do they utilize the highest quality materials and alloys?

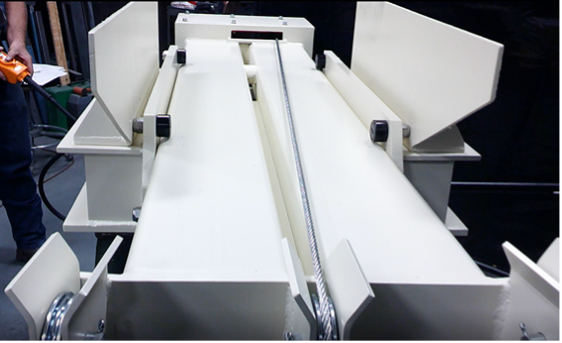

As a metal fabricator, it is important to supply precision metal products, heavy structural steel and plate fabrication, and sheet metal. A good fabricator offers services such as cutting, fitting, welding, testing, finishing, painting, and assembly.

2. Engineering skills

Does your fabricator have skilled engineers that pay attention to details and ensure that the equipment and parts are made specifically for your application?

Offering added services such as engineering and custom design to the fabrication is a plus. Make sure the fabricator has designers who work from any standard engineering drawings or plans and provide industrial design services.

3. Installation and turn-around

Can your fabricator install and deliver with a short turnaround?

If a project requires both fabrication and field installation, choose a fabricator that has the capabilities to tackle many types of projects as well as emergency repairs, training, and calibration. Also, keep in mind that choosing a fabrication shop that is centrally located will allow you to have more control of your products and lead time.

If you need conveyor modifications, hoists, catwalks, platforms, safety upgrades, and other fabrications for your expansion plans, be sure to tap the kind of expertise that can help you avoid mistakes, minimize costs, and ensure success.

Give us a call (503-213-2013) or email us to schedule a consultation and understand your fabrication needs.

Who are we?

Crow Engineering is a multi-discipline consulting engineering firm serving mechanical, structural, and civil engineering needs for a variety of industries.

Engineering Services

the crow connection

Recent News

The Crow Connection delivers high-level insights on engineering, automation, and process optimization, helping you drive efficiency and innovation. Covering topics like AI-powered automation, manufacturing strategies, and industrial process improvements, it’s a must-read for leaders seeking a competitive edge.