Many investments and upgrade projects continue to emerge in the US South

The industry knows that the US needs to add about 1.5 million new homes per year to keep pace with population growth and replace existing homes. Forecasters indicate that lumber capacity in North America will fall short of new demand by close to 7 BBF which is equivalent to more than 20 large-capacity sawmills.

The time is now for a structural assessment

To ensure safety and minimize the risk of operational shutdowns at a time of high demand, many mills commission a structural assessment of critical facilities. Such assessments typically involve an analysis and evaluation of foundations, framings, and associated construction systems and details.

Can’t Fill Your Manufacturing Jobs? Read This Before It’s too Late: 3 Keys to Attracting and Keeping Manufacturing Employees

In March 2021, activity in the sector surged to a 37-year high. An estimated half million jobs in manufacturing remain unfilled. Across the spectrum – from low-skilled entry-level positions to specialized roles such as welders and machinists — factory operators find it increasingly difficult to find the workers they need.

Looking to Upgrade a Conveyor? Ask These Questions First

When it comes to upgrading conveyors, it’s important to move deliberately. For starters, you’ll need to assess the space, infrastructure, and equipment in place.

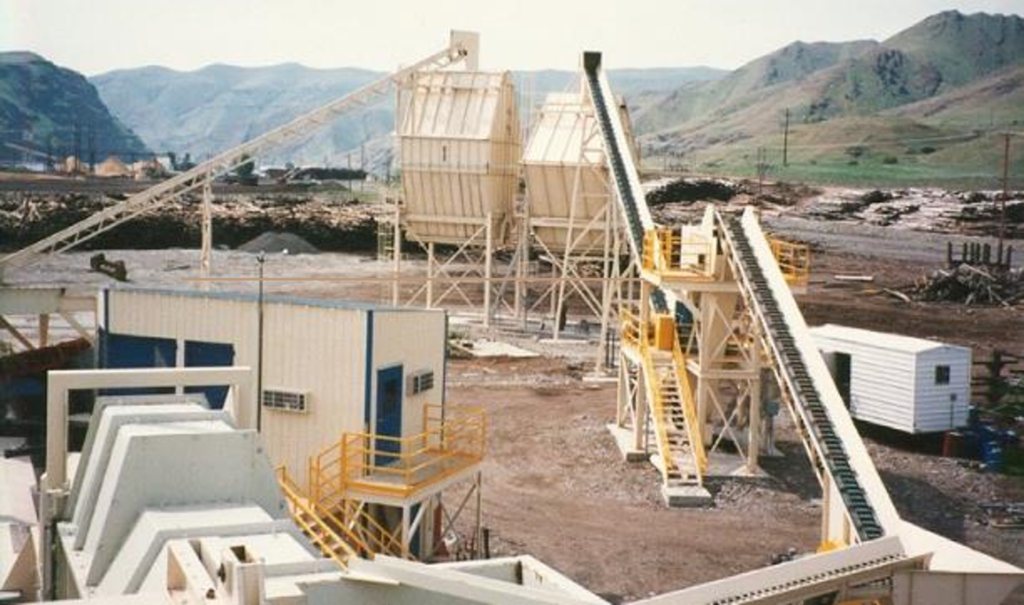

Why Plant Modernization? Four Reasons to Go with a Brownfield Expert

Structures and equipment don’t last forever. At some point, they begin to exhibit signs of wear and tear. Eventually, you need to take action. Which is what ‘brownfield” plant modernization is all about. There’s a lot of value in the equipment you already have – and with plant modernization, you can keep on generating value for years to come.

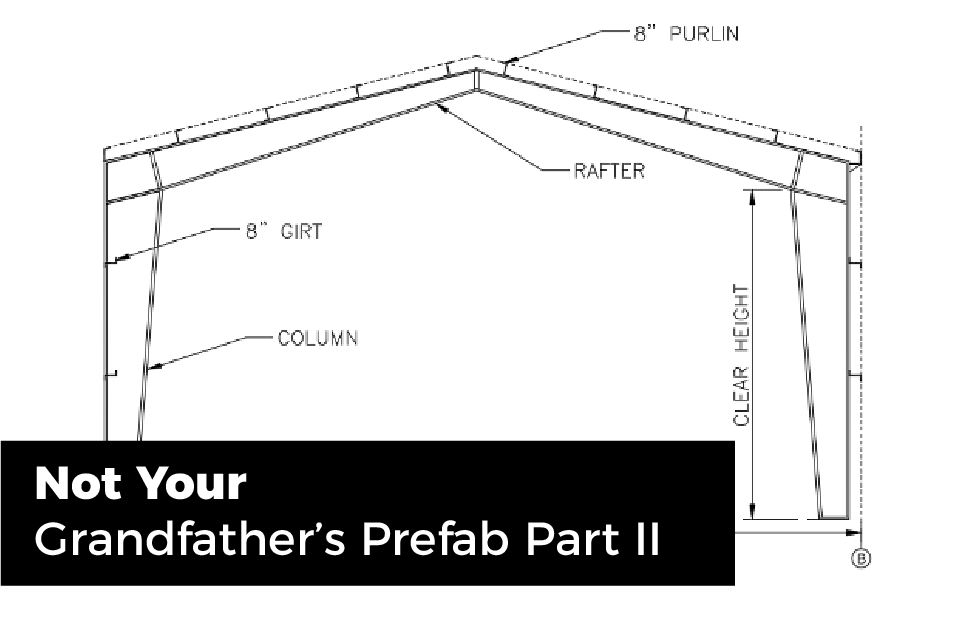

Specification and Design of Pre-engineered Metal Buildings (Part II)

In the first part of this article, we looked at the basics and dimensions of metal buildings for industrial settings. In this second part of the article, we explain the design criteria and specifications of pre-engineered metal buildings.

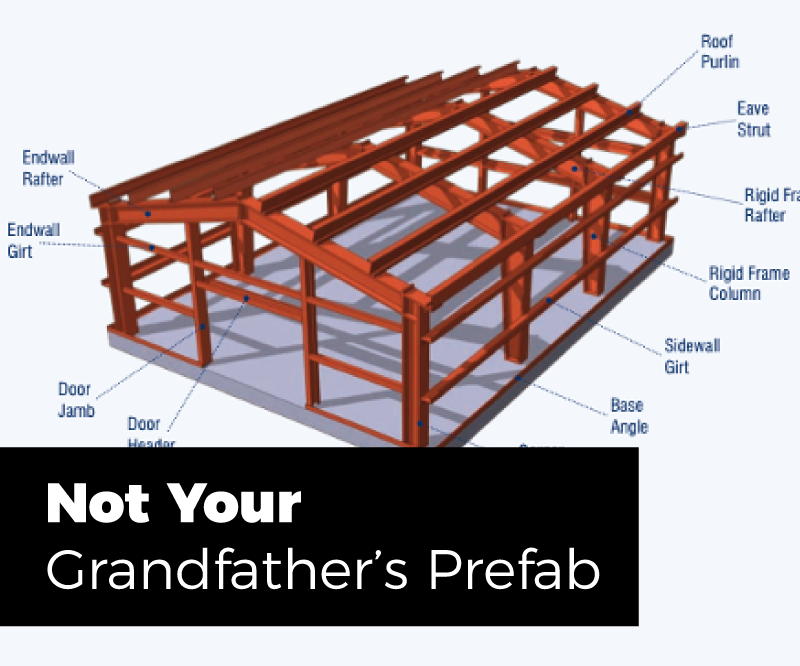

Specification and Design of Pre-engineered Metal Buildings (Part I)

Pre-engineered metal buildings are common features in industrial settings. In fact, they have become common features in many types of construction from utilitarian sheds to keep out the elements to multi-story architectural buildings for just about any use. This is the first part of an article looking at specifying metal buildings for industrial settings.

Helping Sawmills Manage Demand

Crow has helped customers save millions of dollars in capital expenses by re-purposing current facilities and equipment on site. If you’re in the lumber business, it’s hardly news that demand has been outstripping supply – largely due to a pandemic housing boom that few saw coming. With new home building reaching a 15-year high, demand for new building materials such as 2×4 lumber is through the roof.

Why Risk Based Safety?

Keep the risk low, keep employees safe, and keep operations up and running – which keeps the revenue flowing.

Who are we?

Crow Engineering is a multi-discipline consulting engineering firm serving mechanical, structural, and civil engineering needs for a variety of industries.