Freres Lumber Builds a New Breezeway

Freres Lumber Co. Inc. is known for innovation. Take, for instance, its new-to-market patented, engineered wood product: mass plywood panels (MPP).

MPP is a unique product that competes directly with the popular cross-laminated timber (CLT) products – which were originally developed in Europe and are now produced by several manufacturers in the US and Canada. Where CLT utilizes dimensional lumber laminated in layers in alternating directions, MPP uses a thin veneer to fortify the wood and augment it with dimensional stability.

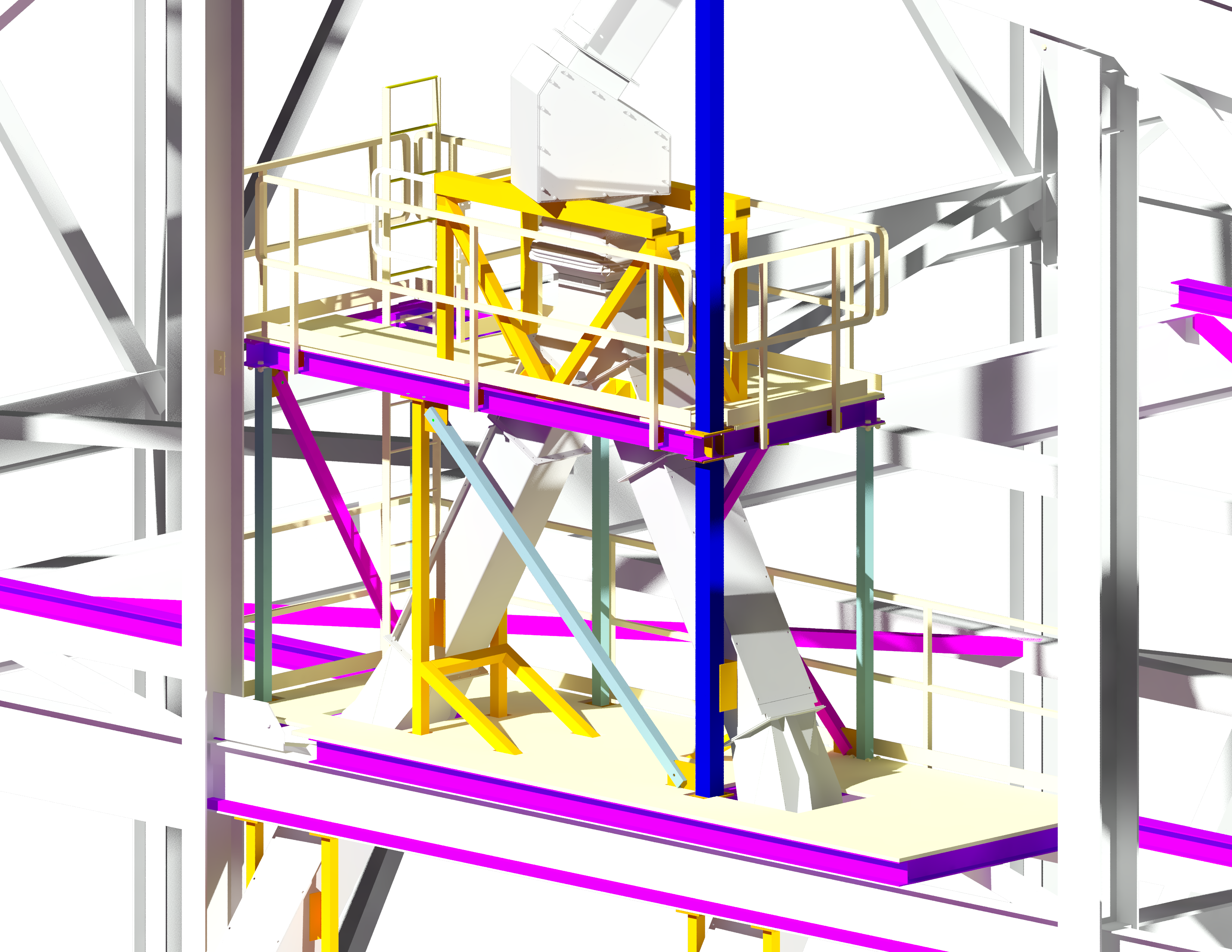

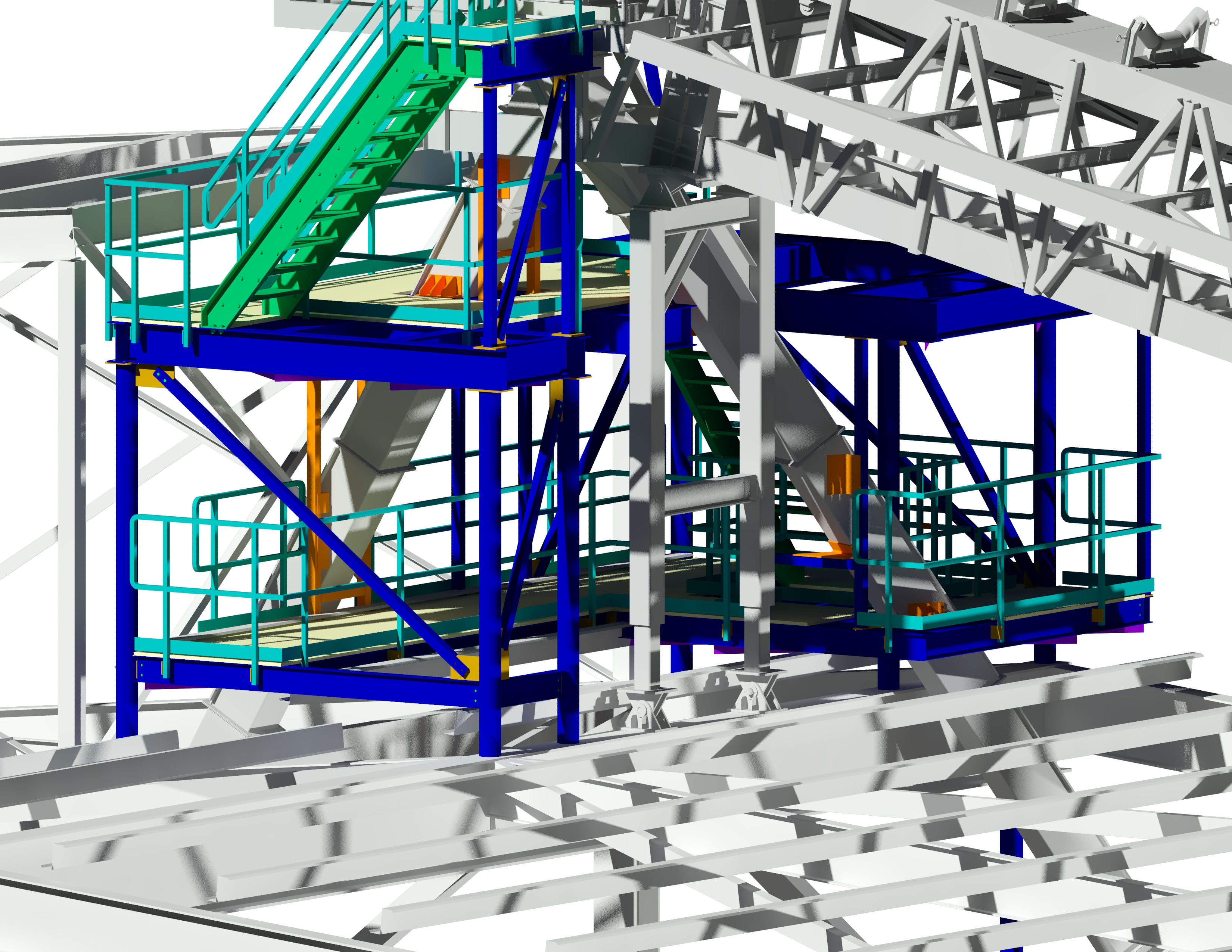

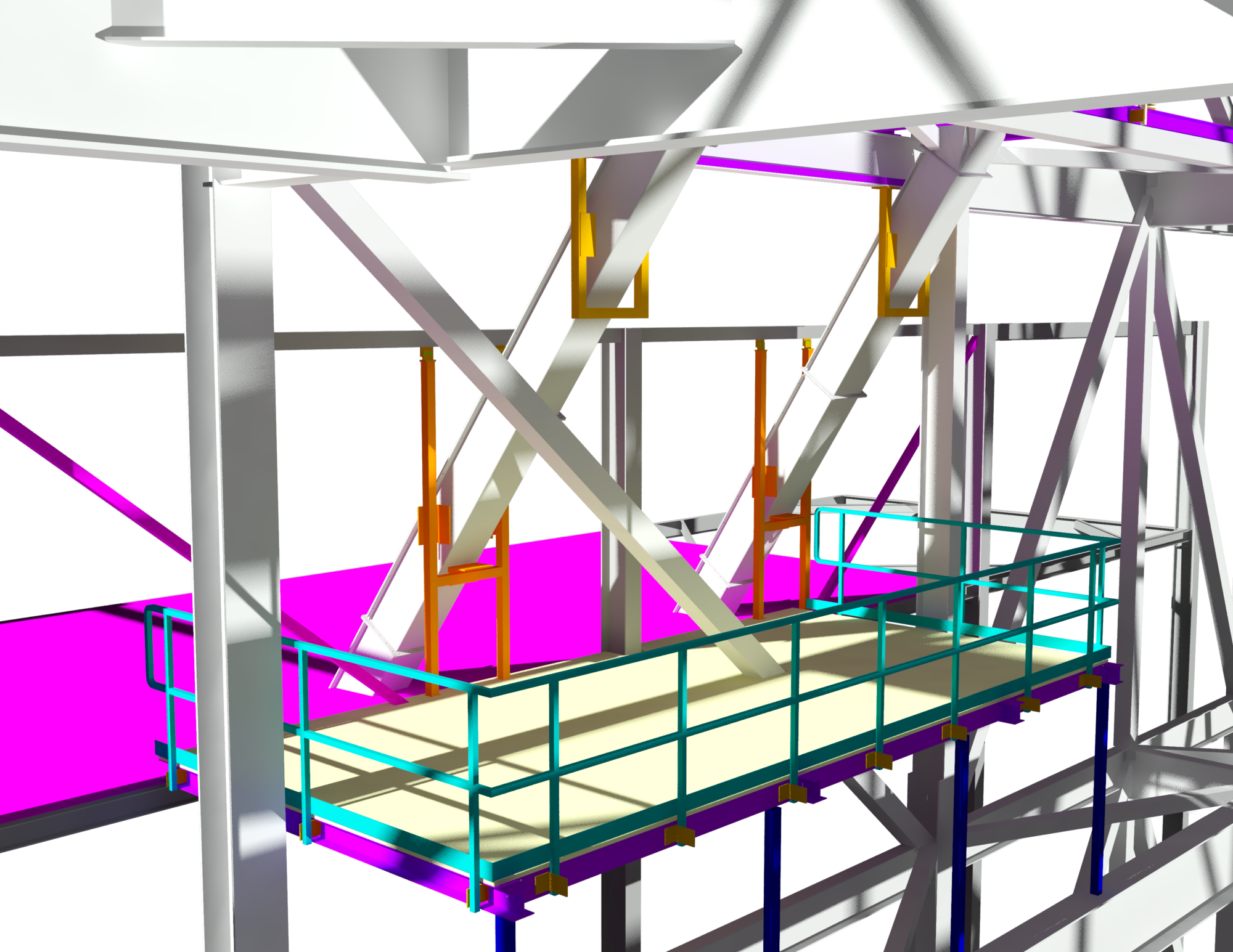

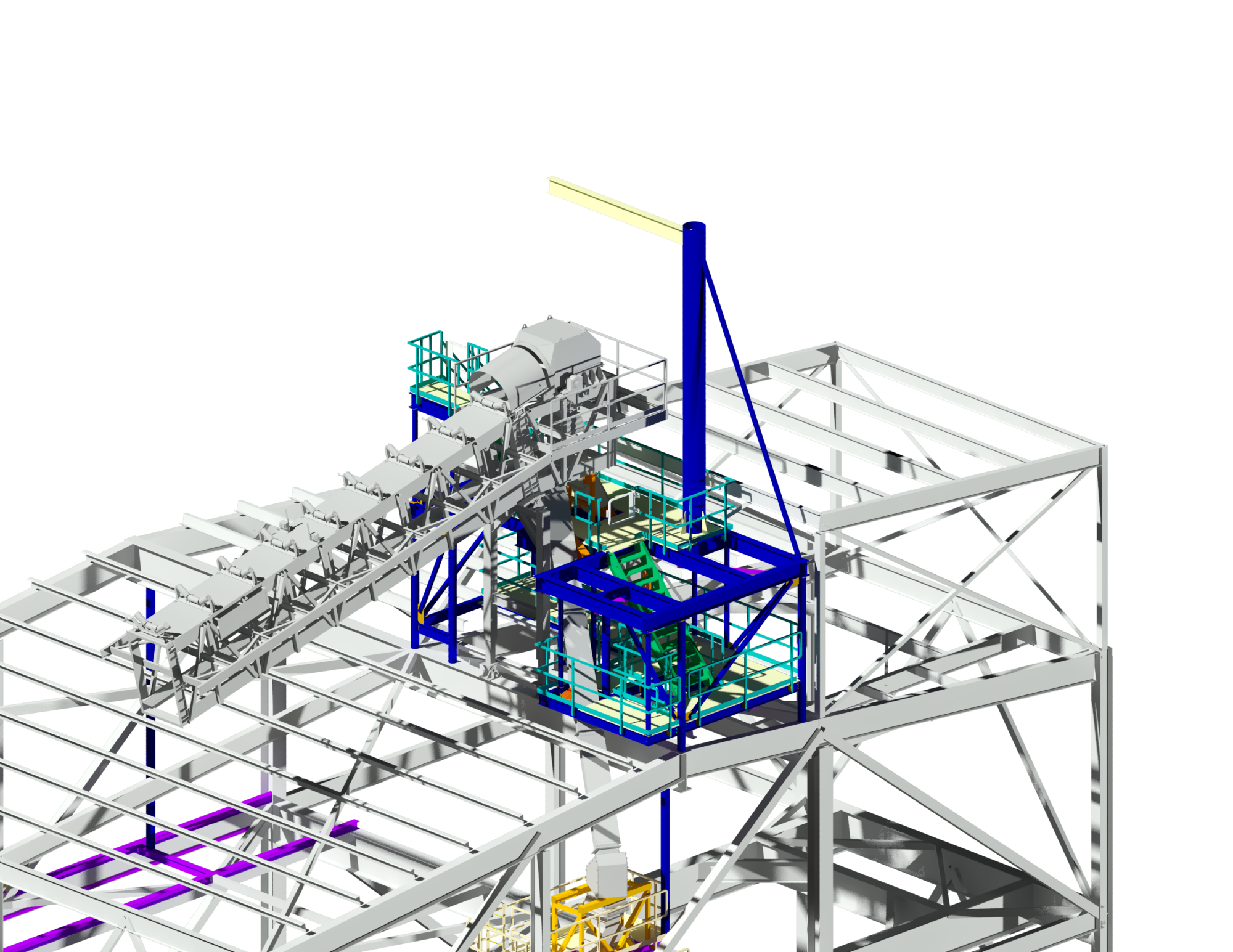

Recently, Freres worked with Crow Engineering to design an open-sided structure using its MPP product. The aim of the project was to infill a space between two manufacturing buildings at the Freres Plant 3 mill in Mill City, OR.

With the project complete, Freres now enjoys a structure that is 43 feet wide by 109 feet long, open on the ends to allow trucks and forklifts to pass between the buildings, while providing weather protection for materials being transferred from one building to the other.

The use of heavier MPP materials gives the infill building greater fire resistance than the adjacent light-framed timber buildings. The dimensions of the MPP materials used in this project would qualify it as a Type IV Heavy Timber building per the IBC code. However, since it is not separated from the adjacent structures by fire separation walls, it is still classified as Type V-B.

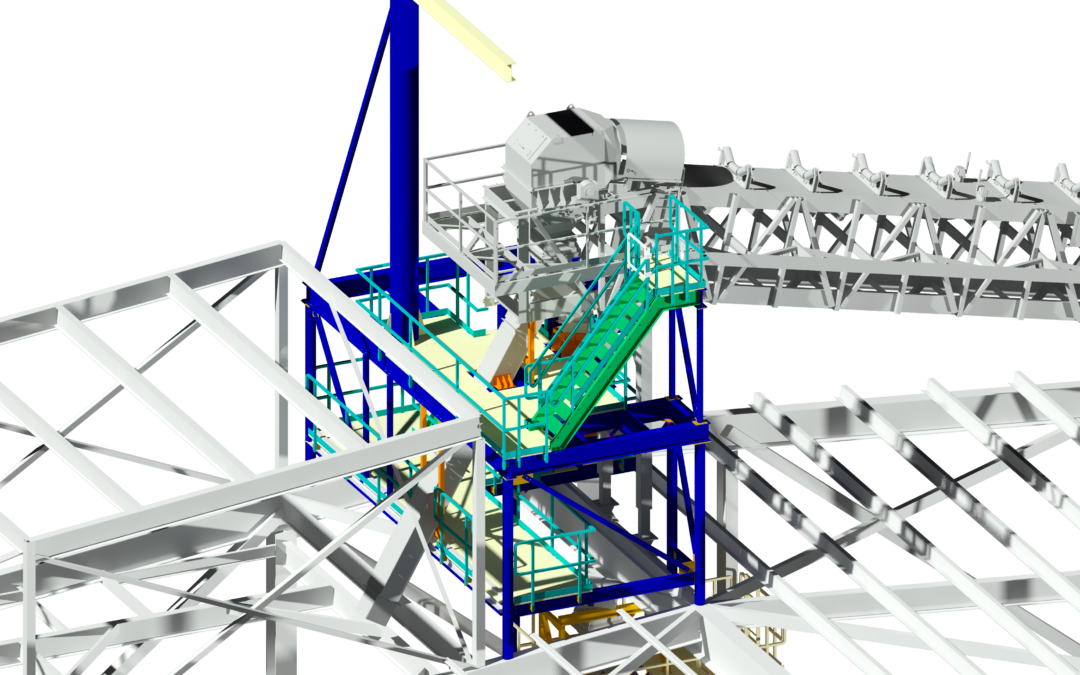

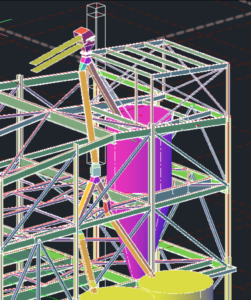

After modeling the structure in Revit, the Crow team created 3D files and shop drawings for Freres to import into their system. From there, Freres created the files to control the CNC machine to cut the parts. Freres also sent files to the contractor for cutting steel connection plates – while construction documents were prepared from the Revit model for permitting and construction.

For us here at Crow, this project demonstrates the viability of MPP as a high-quality building material that can serve as an alternative not only to CLT but to concrete and steel as well. We thank Freres for the chance to learn and contribute.

John Bradford. Sr. Structural Engineer