No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

Structural Engineer: John F. Bradford, PE, SE

Crow Engineering was selected to be the prime consultant to the owner of the Columbia Colstor Facility in Quincy, Washington. Our team provided the foundation engineering, structural engineering, and facility planning and engineering, while we coordinated a sub-consultant to take care of the mechanical, electrical, and plumbing.

This was a Green Field Project to build a 260,000 square foot freezer facility with truck and rail docks, offices, shop, and machinery rooms. The rail dock with large roll-up doors is an over-width chilled dock that allows chilled product storage. The facility was partially constructed with refurbished long-span structural steel trusses, columns, and beams that were modified and reused from a dismantled wood products facility.

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

Kennewick, Washington

ENGINEER: John F. Bradford, PE, SE

Crow Engineering was selected to be the prime consultant to build a new facility in Kennewick, Washington. This Greenfield project was a 265,000 square foot cold storage warehouse with rail and truck service, along with a complete facility including offices, engine room, shops, and employee facilities.

SERVICES

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

Crow Engineering is modeling SnoTemp’s cash flow requirements and building project contingencies. Our consulting efforts will enable them to confidently purchase and develop property that fit both within their financial and operational success parameters.

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

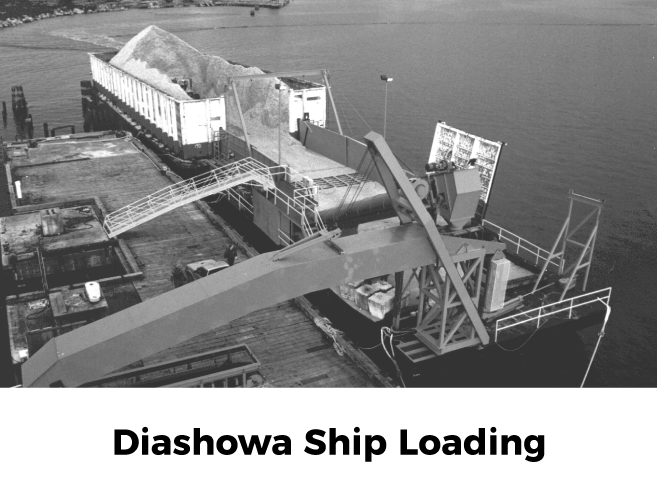

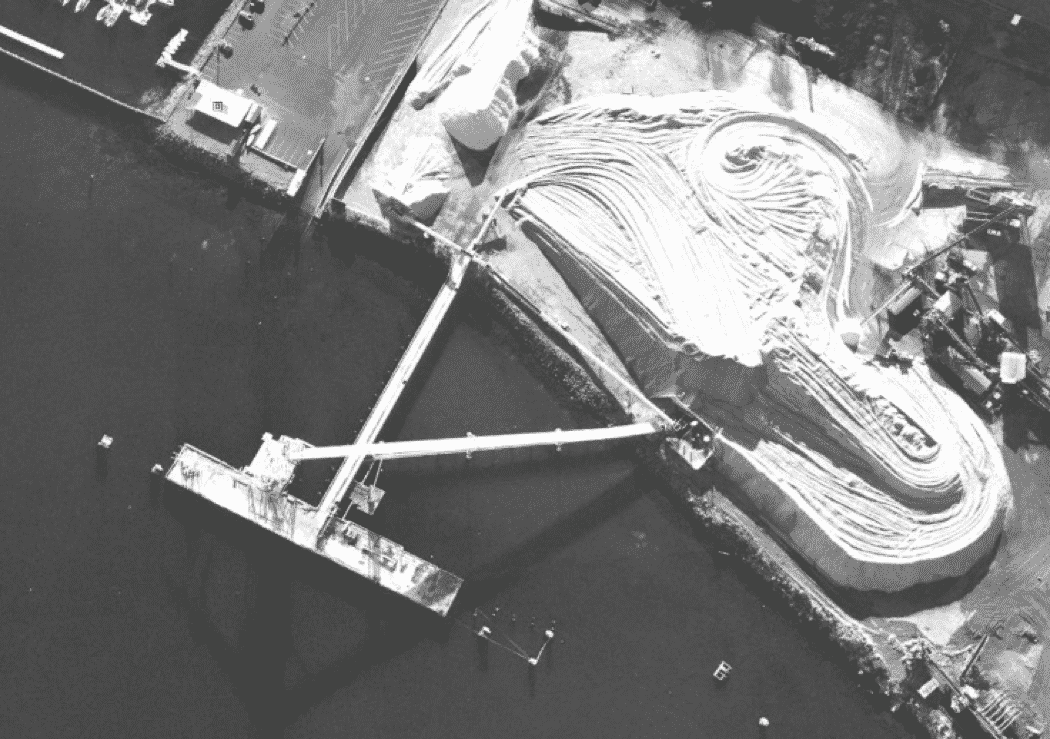

Port Angeles, Washington

Crow Engineering provided the project engineering and conveyor system design on chip plant modifications and a new ship loading facility installation. The goal was to increase the chip-loading rate from 400 TPH to 1200 TPH without causing any additional chip discharge to the waterway.

The capacity of the existing reclaim conveyor was increased by threefold. A new 60″ wide conveyor (86 feet tall and 430 feet long) was installed to convert the system from a “long-blow” system to a “short-blow” system. A new tower with a ship-loading boom was installed on a new marine foundation.

During Phase 2, Crow Engineering was hired to design a state-of-the-art barge unloading system including the “Slave Barge,” onboard chip reclaim conveyor and transition conveyor, new articulating conveyor to dock, 250 feet long dock-supported chip conveyor, and rotary stacker for pile creation.

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

Keizer, Oregon

STRUCTURAL ENGINEER: John F. Bradford, PE, SE

PARTNERS/VENDORS: Elcon Associates, Inc.

Crow Engineering provided structural engineering and design for the Wheatland Ferry Electrification Project. Both towers that span the Willamette River required a height increase and a new cable support system for the electrification of the ferry. During the project, Crow Engineering oversaw structural support and construction observation.